Общий каталог Yamawa 2021 - страница 684

Навигация

13. Introduction to Thread Forming Taps (Roll Taps)

Intro

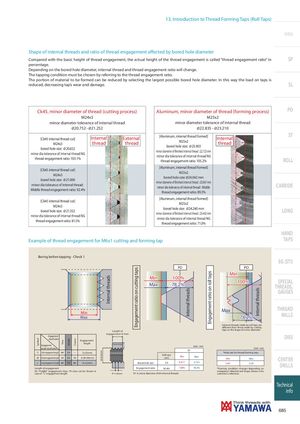

Shape of internal threads and ratio of thread engagement affected by bored hole diameter

Compared with the basic height of thread engagement, the actual height of the thread engagement is called “thread engagement ratio” in SP

percentage.

Depending on the bored hole diameter, internal thread and thread engagement ratio will change.

The tapping condition must be chosen by referring to the thread engagement ratio.

The portion of material to be formed can be reduced by selecting the largest possible bored hole diameter. In this way the load on taps is

reduced, decreasing tap’s wear and damage. SL

Ck45, minor diameter of thread (cutting process) Aluminum, minor diameter of thread (forming process) PO

M24x3 M25x2

minor diameter tolerance of internal thread minor diameter tolerance of internal thread

Ø20.752 - Ø21.252 Ø22.835 - Ø23.210

[Ck45 internal thread cut] InternalM24x3threadbored hole size: Ø20.652minor dia tolerance of internal thread NGthread engagement ratio: 103.1%Externalthread[Aluminum, internal thread formed] InternalM25x2threadbored hole size: Ø23.903minor diameter of finished internal thread : 22.723 mmminor dia tolerance of internal thread NGthread engagement ratio: 105.2%STROLL

[Ck45 internal thread cut]M24x3bored hole size: Ø21.000minor dia tolerance of internal thread:Middle thread engagement ratio: 92.4% [Aluminum, internal thread formed]M25x2bored hole size: Ø24.042 mmminor diameter of finished internal thread : 23.067 mmminor dia tolerance of internal thread : MiddleCARBIDEthread engagement ratio: 89.3%

[Ck45 internal thread cut]M24x3bored hole size: Ø21.352minor dia tolerance of internal thread NGthread engagement ratio: 81.5% [Aluminum, internal thread formed]M25x2bored hole size: Ø24.240 mmminor diameter of finished internal thread : 23.462 mmminor dia tolerance of internal thread NGthread engagement ratio: 71.0%LONG

HAND

Example of thread engagement for M6x1 cutting and forming tap TAPS

Boring before tapping - Check 1

EG (STI)

PD PD

Min

Min 100%Max78.2% 100% SPECIALTHREADS,

GAUGES

MinMax Max THREAD748.12%MILLS

Internal threads made by roll taps are

different from those made by cutting

Length of taps on the shape of minor diameter.

engagement=9.1mm

Engagementclassification Engagement DIES

Engagement length Internal threads Unit : mm

length classification Unit : mm

D1

S Short engagement length 4H 5H — S≤3(mm) External threads *Hole size for thread forming taps

M Normal engagement length 5H 6H 7H 3

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали