Общий каталог Yamawa 2021 - страница 682

Навигация

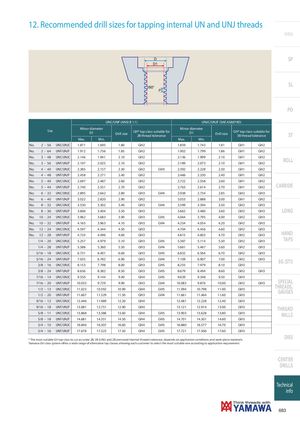

12. Recommended drill sizes for tapping internal UN and UNJ threads Intro SP SL PO UNC/UNF (ANSI B 1.1) UNJC/UNJF (SAE AS8879D) Size Minor diameter Minor diameterD1Drill sizeGH* tap class suitable for2B thread toleranceD1Drill sizeGH* tap class suitable for3B thread toleranceST Max. Min. Max. Min. No. 2 - 56 UNC/UNJC 1.871 1.695 1.80 GH2 1.859 1.743 1.81 GH1 GH2 No. 2 - 64 UNF/UNJF 1.912 1.756 1.85 GH2 1.902 1.799 1.86 GH1 GH2 No. 3 - 48 UNC/UNJC 2.146 1.941 2.10 GH2No.3 - 56UNF/UNJF2.1972.0252.10GH22.1361.999 2.10 GH1 GH22.1892.0732.10GH1GH2ROLL No. 4 - 40 UNC/UNJC 2.385 2.157 2.30 GH2 GH3 2.392 2.228 2.30 GH1 GH2 No. 4 - 48 UNF/UNJF 2.458 2.271 2.40 GH2 2.466 2.330 2.40 GH1 GH2 No. 5 - 40 UNC/UNJC 2.697 2.487 2.60 GH2 2.722 2.558 2.60 GH1 GH2 No. 5 - 44 UNF/UNJF 2.740 2.551 2.70 GH2 2.763 2.614 2.70 GH1 GH2 CARBIDE No. 6 - 32 UNC/UNJC 2.895 2.642 2.80 GH3 GH4 2.938 2.734 2.85 GH2 GH3 No. 6 - 40 UNF/UNJF 3.022 2.820 2.90 GH2 3.053 2.888 3.00 GH1 GH2 No. 8 - 32 UNC/UNJC 3.530 3.302 3.40 GH3 GH4 3.599 3.394 3.50 GH2 GH3 No. 8 - 36 UNF/UNJF 3.606 3.404 3.50 GH3 3.662 3.480 3.60 GH2 GH3 LONG No. 10 - 24 UNC/UNJC 3.962 3.683 3.90 GH3 GH5 4.064 3.795 4.00 GH2 GH3 No. 10 - 32 UNF/UNJF 4.165 3.963 4.10 GH3 GH4 4.254 4.054 4.20 GH2 GH3 No. 12 - 24 UNC/UNJC 4.597 4.344 4.50 GH3 4.704 4.456 4.60 GH2 GH3 No. 12 - 28 UNF/UNJF 4.724 4.496 4.60 GH3 4.815 4.603 4.70 GH2 GH3 HAND 1/4 - 20 UNC/UNJC 5.257 4.979 5.10 GH3 GH5 5.387 5.114 5.30 GH2 GH3 TAPS 1/4 - 28 UNF/UNJF 5.588 5.360 5.50 GH3 GH4 5.661 5.467 5.60 GH2 GH3 5/16 - 18 UNC/UNJC 6.731 6.401 6.60 GH3 GH5 6.832 6.564 6.70 GH2 GH3 5/16 - 24 UNF/UNJF 7.035 6.782 6.90 GH3 GH4 7.109 6.907 7.00 GH2 GH3 EG (STI) 3/8 - 16 UNC/UNJC 8.153 7.798 8.00 GH3 GH5 8.255 7.979 8.10 GH3 3/8 - 24 UNF/UNJF 8.636 8.382 8.50 GH3 GH5 8.679 8.494 8.60 GH2 GH3 7/16 - 14 UNC/UNJC 9.550 9.144 9.40 GH4 GH5 9.639 9.348 9.50 GH3 7/16 - 20 UNF/UNJF 10.033 9.729 9.90 GH3 GH4 10.083 9.876 10.00 GH2 GH3 SPECIAL 1/2 - 13 UNC/UNJC 11.023 10.592 10.90 GH4 GH5 11.094 10.798 11.00 GH3 THREADS,GAUGES 1/2 - 20 UNF/UNJF 11.607 11.329 11.50 GH3 GH4 11.661 11.464 11.60 GH3 9/16 - 12 UNC/UNJC 12.446 11.989 12.20 GH4 12.481 12.228 12.40 GH3 9/16 - 18 UNF/UNJF 13.081 12.751 12.90 GH4 13.121 12.914 13.00 GH3 THREAD 5/8 - 11 UNC/UNJC 13.868 13.386 13.60 GH4 GH5 13.903 13.628 13.80 GH3 MILLS 5/8 - 18 UNF/UNJF 14.681 14.351 14.50 GH4 GH5 14.701 14.501 14.60 GH3 3/4 - 10 UNC/UNJC 16.840 16.307 16.60 GH4 GH5 16.880 16.577 16.70 GH3 3/4 - 16 UNF/UNJF 17.678 17.323 17.50 GH4 GH5 17.721 17.506 17.60 GH3 * The most suitable GH tap class to cut accurate 2B, 3B (UNJ) and 2B oversized internal threads tolerance, depends on application conditions and work-piece materials. DIES Yamawa GH class system offers a wide range of alternative tap classes allowing each customer to select the most suitable one according to application requirement. CENTER DRILLS Technical info 683

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали