Общий каталог Yamawa 2021 - страница 659

Навигация

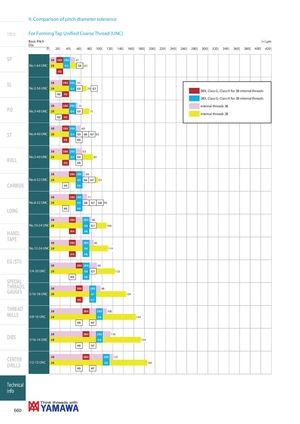

9. Comparison of pitch diameter tolerance Intro For Forming Tap Unified Coarse Thread (UNC) Basic Pitch (+) μm Dia. 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 SP 3B 3BX 2BX 47 No.1-64 UNC 2B G3 G5 65 H2 SL 3B 3BX 2BX 53 No.2-56 UNC 2B G4 G5 70 G7 3BX, Class G, Class H for 3B internal threads H2 H3 2BX, Class G, Class H for 2B internal threads 3B 3BX 2BX 55 internal threads 3B PO No.3-48 UNC 2B G4 G5 75 internal threads 2B H2 H3 3B 3BX 2BX 60 ST No.4-40 UNC 2B G4 G5 G6 G7 83 H3 H5 3B 3BX 2BX 63 ROLL No.5-40 UNC 2B G4 G5H3H5 83 3B 3BX 2BX 68 No.6-32 UNC 2B G5 G6 G7 93 CARBIDE H3 H5 3B 3BX 2BX 71 No.8-32 UNC 2B G5 G6 G7 G8 96 LONG H3 H5 3B 3BX 2BX 80 No.10-24 UNC 2B G6 G7 108 HAND, H4 H6 TAPS 3B 3BX 2BX 82 No.12-24 UNC 2B G6 110 H4 H6 EG (STI) 3B 3BX 2BX 90 1/4-20 UNC 2B G6 G7 123 H4 H6 SPECIAL THREADS,GAUGES5/16-18 UNC 3B2B 3BX 2BX 98G7 134 H5 H7 THREAD 3B 3BX 2BX 108 MILLS 3/8-16 UNC 2B G8 144 H5 H7 DIES 3B7/16-14 UNC2B 3BX 2BX 116G8 154 H5 H7 CENTER 3B 3BX 2BX 121 DRILLS 1/2-13 UNC 2B G9 165 H5 H7 Technical info 660

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали