Общий каталог Yamawa 2021 - страница 635

Навигация

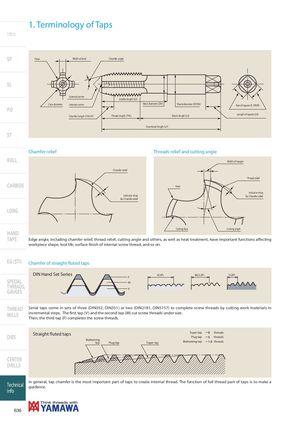

1. Terminology of Taps Intro SP Flute Width of land Chamfer angle SL External center Usable length (LU) Core diameter Internal center Neck diameter (DN) Shank diameter (DCON) Size of square (K -DRVS) PO Chamfer length (THCHT) Thread length (THL) Shank length (LS) Length of square (LK) Functional length (LF) ST Chamfer relief Threads relief and cutting angle ROLL Width of margin Chamfer relief Thread relief CARBIDE Heel Indicator drop Indicator drop for Chamfer relief for Chamfer relief LONG Cutting face Cutting angle HAND TAPS Edge angle, including chamfer relief, thread relief, cutting angle and others, as well as heat treatment, have important functions affecting workpiece shape, tool life, surface finish of internal screw thread, and so on. EG (STI) Chamfer of straight fluted taps DIN Hand Set Series F V(5P) M(3.5P) F(2P) SPECIAL M THREADS,GAUGES V THREAD Serial taps come in sets of three (DIN352, DIN351) or two (DIN2181, DIN5157) to complete screw threads by cutting work materials in MILLS incremental steps. The first tap (V) and the second tap (M) cut screw threads under size.Then, the third tap (F) completes the screw threads. DIES Straight fluted taps Bottomingtap Plug tap Taper tap threadsPlug tapthreadsTaper tapBottoming tapthreads CENTER DRILLS Technical In general, tap chamfer is the most important part of taps to create internal thread. The function of full thread part of taps is to make aguidance. info 636

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали