Общий каталог Yamawa 2021 - страница 625

Навигация

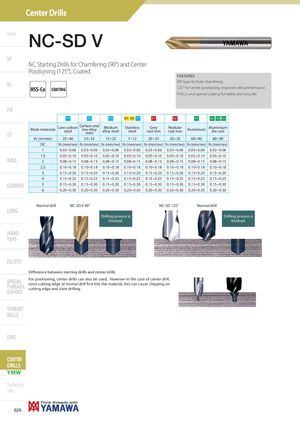

Center Drills Intro NC-SD V SP NC Starting Drills for Chamfering (90°) and Center Positioning (125°), Coated FEATURES SL HSS-Co COATING 90° type for hole chamfering.125° for center positioning, improves drill performance. HSSCo and special coating for stable and long life. PO P1 P2 P3 M1 M2 P7 K1 K2 N1 N2 N3 N4 ST Work-materials Low carbon steel Carbon and low alloy steel Mediumalloy steelStainlesssteelGreycast ironNodularcast ironAluminiumAluminiumdie cast Vc (m/min) 25÷40 25÷32 15÷25 7÷12 20÷35 20÷35 60÷90 60÷90 DC fn (mm/rev) fn (mm/rev) fn (mm/rev) fn (mm/rev) fn (mm/rev) fn (mm/rev) fn (mm/rev) fn (mm/rev) 1 0.03÷0.06 0.03÷0.06 0.03÷0.06 0.03÷0.06 0.03÷0.06 0.03÷0.06 0.03÷0.06 0.03÷0.06 1.5 0.05÷0.10 0.05÷0.10 0.05÷0.10 0.05÷0.10 0.05÷0.10 0.05÷0.10 0.05÷0.10 0.05÷0.10 ROLL 2 0.08÷0.15 0.08÷0.15 0.08÷0.15 0.08÷0.15 0.08÷0.15 0.08÷0.15 0.08÷0.15 0.08÷0.15 2.5 0.10÷0.18 0.10÷0.18 0.10÷0.18 0.10÷0.18 0.10÷0.18 0.10÷0.18 0.10÷0.18 0.10÷0.18 YMW-NC-SD V 3 0.15÷0.20 0.15÷0.20 0.15÷0.20 0.15÷0.20 0.15÷0.20 0.15÷0.20 0.15÷0.20 0.15÷0.20 4 0.15÷0.25 0.15÷0.25 0.15÷0.25 0.15÷0.25 0.15÷0.25 0.15÷0.25 0.15÷0.25 0.15÷0.25 CARBIDE 5 0.15÷0.30 0.15÷0.30 0.15÷0.30 0.15÷0.30 0.15÷0.30 0.15÷0.30 0.15÷0.30 0.15÷0.30 6 0.20÷0.30 0.20÷0.30 0.20÷0.30 0.20÷0.30 0.20÷0.30 0.20÷0.30 0.20÷0.30 0.20÷0.30 Normal drill NC-SD V 90° NC-SD 125° Normal drill LONG Drilling process is Drilling process is finished. finished. HAND TAPS EG (STI) Difference between starting drills and center drills SPECIALTHREADS,GAUGESFor positioning, center drills can also be used. However in the case of center drill,since cutting edge of normal drill first hits the material, this can cause chipping oncutting edge and slant drilling. THREAD MILLS DIES CENTER DRILLS YMW Technical info 626

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали