Общий каталог Yamawa 2021 - страница 530

Навигация

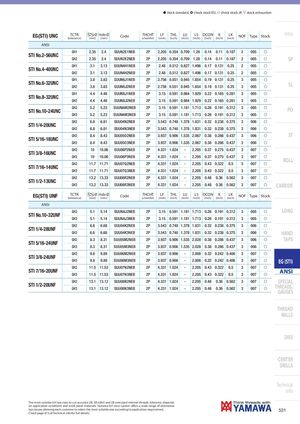

h stock standard, ) check stock EU, f check stock JP, m stock exhaustion EG(STI) UNC TCTR Ø Hole Ø(tolerance)(mm)(mm)CodeTHCHT(chamfer)LF(inch)THL(inch) LU(inch) LS DCON K(inch)(inch)(inch)LK(inch)NOFTypeStockIntro ANSI GH1 2.35 2.4 SUUN2E1NEB 2P 2.205 0.354 0.709 1.28 0.14 0.11 0.187 2 005 f STI No.2-56UNC GH2 2.35 2.4 SUUN2E2NEB 2P 2.205 0.354 0.709 1.28 0.14 0.11 0.187 2 005 f SP GH1 3.1 3.13 SUUN4H1NEB 2P 2.48 0.512 0.827 1.496 0.17 0.131 0.25 2 005 f STI No.4-40UNC GH2 3.1 3.13 SUUN4H2NEB 2P 2.48 0.512 0.827 1.496 0.17 0.131 0.25 2 005 f GH1 3.8 3.83 SUUN6J1NEB 2P 2.756 0.551 0.945 1.654 0.19 0.131 0.25 3 005 f STI No.6-32UNC GH2 3.8 3.83 SUUN6J2NEB 2P 2.756 0.551 0.945 1.654 0.19 0.131 0.25 3 005 f SL GH1 4.4 4.48 SUUN8J1NEB 2P 3.15 0.591 0.984 1.929 0.22 0.165 0.281 3 005 f STI No.8-32UNC GH2 4.4 4.48 SUUN8J2NEB 2P 3.15 0.591 0.984 1.929 0.22 0.165 0.281 3 005 f GH2 5.2 5.23 SUUNAM2NEB 2P 3.15 0.591 1.181 1.713 0.26 0.191 0.312 3 005 fSTI No.10-24UNCPO GH3 5.2 5.23 SUUNAM3NEB 2P 3.15 0.591 1.181 1.713 0.26 0.191 0.312 3 005 f GH2 6.8 6.81 SUU04N2NEB 2P 3.543 0.748 1.378 1.831 0.32 0.238 0.375 3 006 f STI 1/4-20UNC GH3 6.8 6.81 SUU04N3NEB 2P 3.543 0.748 1.378 1.831 0.32 0.238 0.375 3 006 f GH2 8.4 8.43 SUU05O2NEB 2P 3.937 0.906 1.535 2.067 0.38 0.286 0.437 3 006 f ST STI 5/16-18UNC GH3 8.4 8.43 SUU05O3NEB 2P 3.937 0.906 1.535 2.067 0.38 0.286 0.437 3 006 f GH2 10 10.06 SUU06P2NEB 2P 4.331 1.024 - 2.205 0.37 0.275 0.437 3 007 f STI 3/8-16UNC GH3 10 10.06 SUU06P3NEB 2P 4.331 1.024 - 2.205 0.37 0.275 0.437 3 007 f GH2 11.7 11.71 SUU07Q2NEB 2P 4.331 1.024 - 2.205 0.43 0.322 0.5 3 007 f ROLL STI 7/16-14UNC GH3 11.7 11.71 SUU07Q3NEB 2P 4.331 1.024 - 2.205 0.43 0.322 0.5 3 007 f GH2 13.2 13.33 SUU08R2NEB 2P 4.331 1.024 - 2.205 0.48 0.36 0.562 3 007 f STI 1/2-13UNC GH3 13.2 13.33 SUU08R3NEB 2P 4.331 1.024 - 2.205 0.48 0.36 0.562 3 007 f CARBIDE EG(STI) UNF TCTR Ø Hole Ø(tolerance)(mm)(mm)CodeTHCHT(chamfer)LF(inch)THL(inch) LU(inch) LS DCON K(inch)(inch)(inch)LK(inch)NOFTypeStock ANSI GH2 5.1 5.14 SUUNAJ2NEB 2P 3.15 0.591 1.181 1.713 0.26 0.191 0.312 3 005 f LONG STI No.10-32UNF GH3 5.1 5.14 SUUNAJ3NEB 2P 3.15 0.591 1.181 1.713 0.26 0.191 0.312 3 005 f GH2 6.6 6.68 SUU04K2NEB 2P 3.543 0.748 1.378 1.831 0.32 0.238 0.375 3 006 f STI 1/4-28UNF GH3 6.6 6.68 SUU04K3NEB 2P 3.543 0.748 1.378 1.831 0.32 0.238 0.375 3 006 f HAND GH2 8.3 8.31 SUU05M2NEB 2P 3.937 0.906 1.535 2.028 0.38 0.286 0.437 3 006 f TAPS STI 5/16-24UNF GH3 8.3 8.31 SUU05M3NEB 2P 3.937 0.906 1.535 2.028 0.38 0.286 0.437 3 006 f GH2 9.8 9.89 SUU06M2NEB 2P 3.937 0.906 - 2.008 0.32 0.242 0.406 3 007 f STI 3/8-24UNF GH3 9.8 9.89 SUU06M3NEB 2P 3.937 0.906 - 2.008 0.32 0.242 0.406 3 007 f EG (STI) GH2 11.5 11.53 SUU07N2NEB 2P 4.331 1.024 - 2.205 0.43 0.322 0.5 3 007 f STI 7/16-20UNF GH3 11.5 11.53 SUU07N3NEB 2P 4.331 1.024 - 2.205 0.43 0.322 0.5 3 007 f ANSI STI 1/2-20UNF GH2 13.1 13.12 SUU08N2NEB 2P 4.331 1.024 - 2.205 0.48 0.36 0.562 3 007 f SPECIALGH313.113.12SUU08N3NEB2P4.3311.024-2.2050.480.360.5623007fTHREADS,GAUGES THREAD MILLS DIES CENTER DRILLS Technical info The most suitable GH tap class to cut accurate 2B, 3B (UNJ) and 2B oversized internal threads tolerance, depends on application conditions and work-piece materials. Yamawa GH class system offers a wide range of alternative tap classes allowing each customer to select the most suitable one according to application requirement. 531 Check page 673 of Technical info for full details.

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали