Основной каталог Winstar 2021 - страница 92

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

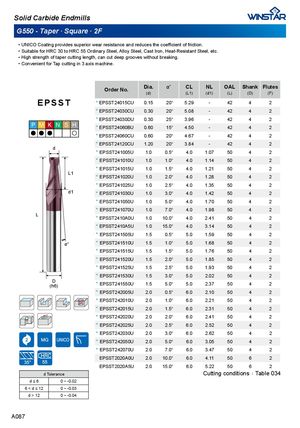

Solid Carbide Endmills G550 - Taper ∙ Square ∙ 2F .UNICO Coating provides superior wear resistance and reduces the coefficient of friction. .Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc. .High strength of taper cutting length, can cut deep grooves without breaking. .Convenient for Tap cutting in 3 axis machine. Order No. Dia. α˚ CL NL OAL Shank Flutes(d)(L1)(d1)(L)(D)(F) EPSST * EPSST24015CU 0.15 20° 5.29 - 42 4 2 * EPSST24030CU 0.30 20° 5.08 - 42 4 2 * EPSST24030DU 0.30 25° 3.96 - 42 4 2 P M K N S H * EPSST24060BU 0.60 15° 4.50 - 42 4 2 ● ● ● ○ * EPSST24060CU 0.60 20° 4.67 - 42 4 2 * EPSST24120CU 1.20 20° 3.84 - 42 4 2 d * EPSST241005U 1.0 0.5° 4.0 1.07 50 4 2 * EPSST241010U 1.0 1.0° 4.0 1.14 50 4 2 * EPSST241015U 1.0 1.5° 4.0 1.21 50 4 2 L1 * EPSST241020U 1.0 2.0° 4.0 1.28 50 4 2 * EPSST241025U 1.0 2.5° 4.0 1.35 50 4 2 d1 * EPSST241030U 1.0 3.0° 4.0 1.42 50 4 2 * EPSST241050U 1.0 5.0° 4.0 1.70 50 4 2 * EPSST241070U 1.0 7.0° 4.0 1.98 50 4 2 L * EPSST2410A0U 1.0 10.0° 4.0 2.41 50 4 2 * EPSST2410A5U 1.0 15.0° 4.0 3.14 50 4 2 * EPSST241505U 1.5 0.5° 5.0 1.59 50 4 2 α° * EPSST241510U 1.5 1.0° 5.0 1.68 50 4 2 * EPSST241515U 1.5 1.5° 5.0 1.76 50 4 2 * EPSST241520U 1.5 2.0° 5.0 1.85 50 4 2 * EPSST241525U 1.5 2.5° 5.0 1.93 50 4 2 * EPSST241530U 1.5 3.0° 5.0 2.02 50 4 2 D(h6) * EPSST241550U 1.5 5.0° 5.0 2.37 50 4 2 * EPSST242005U 2.0 0.5° 6.0 2.10 50 4 2 * EPSST242010U 2.0 1.0° 6.0 2.21 50 4 2 * EPSST242015U 2.0 1.5° 6.0 2.31 50 4 2 * EPSST242020U 2.0 2.0° 6.0 2.41 50 4 2 * EPSST242025U 2.0 2.5° 6.0 2.52 50 4 2 * EPSST242030U 2.0 3.0° 6.0 2.62 50 4 2 * EPSST242050U 2.0 5.0° 6.0 3.05 50 4 2 * EPSST242070U 2.0 7.0° 6.0 3.47 50 4 2 EPSST2020A0U 2.0 10.0° 6.0 4.11 50 6 2 EPSST2020A5U 2.0 15.0° 6.0 5.22 50 6 2 d Tolerance Cutting conditions : Table 034 d≤6 0 ~ -0.02 6 < d ≤ 12 0 ~ -0.03 d > 12 0 ~ -0.04 A087

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020