Основной каталог Winstar 2021 - страница 412

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

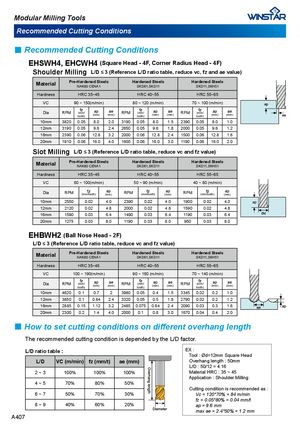

Modular Milling Tools Recommended Cutting Conditions ■ Recommended Cutting Conditions EHSWH4, EHCWH4 (Square Head - 4F, Corner Radius Head - 4F) Shoulder Milling L/D ≤ 3 (Reference L/D ratio table, reduce vc, fz and ae value) Material Pre-Hardened SteelsNAK80 CENA1 Hardened SteelsSKD61,SKD11 Hardened SteelsSKD11,SKH51 Hardness HRC 35~45 HRC 40~55 HRC 55~65 VC 90 ~ 150(m/min) 80 ~ 120 (m/min) 70 ~ 100 (m/min) Dia RPM fz (mm/tooth) ap(mm) ae(mm) RPM fz (mm/tooth) ap(mm) ae(mm) RPM fz (mm/tooth) ap(mm) ae(mm) 10mm 3820 0.05 8.0 2.0 3190 0.05 8.0 1.5 2390 0.05 8.0 1.0 12mm 3190 0.05 9.6 2.4 2650 0.05 9.6 1.8 2000 0.05 9.6 1.2 16mm 2390 0.06 12.8 3.2 2000 0.06 12.8 2.4 1500 0.06 12.8 1.6 20mm 1910 0.06 16.0 4.0 1600 0.06 16.0 3.0 1190 0.06 16.0 2.0 Slot Milling L/D ≤ 3 (Reference L/D ratio table, reduce vc and fz value) Material Pre-Hardened SteelsNAK80 CENA1 Hardened SteelsSKD61,SKD11 Hardened SteelsSKD11,SKH51 Hardness HRC 35~45 HRC 40~55 HRC 55~65 VC 60 ~ 100(m/min) 50 ~ 90 (m/min) 40 ~ 80 (m/min) Dia RPM fz(mm/tooth)ap(mm) RPM fz(mm/tooth)ap(mm) RPM fz(mm/tooth)ap(mm) 10mm 2550 0.02 4.0 2390 0.02 4.0 1900 0.02 4.0 12mm 2120 0.02 4.8 2000 0.02 4.8 1590 0.02 4.8 16mm 1590 0.03 6.4 1490 0.03 6.4 1190 0.03 6.4 20mm 1275 0.03 8.0 1190 0.03 8.0 950 0.03 8.0 EHBWH2 (Ball Nose Head - 2F) L/D ≤ 3 (Reference L/D ratio table, reduce vc and fz value) Material Pre-Hardened SteelsNAK80 CENA1 Hardened SteelsSKD61,SKD11 Hardened SteelsSKD11,SKH51 Hardness HRC 35~45 HRC 40~55 HRC 55~65 VC 100 ~ 190(m/min) 90 ~ 160 (m/min) 70 ~ 140 (m/min) Dia RPM fz (mm/tooth) ap(mm) ae(mm) RPM fz (mm/tooth) ap(mm) ae(mm) RPM fz (mm/tooth) ap(mm) ae(mm) 10mm 4620 0.1 0.7 2 3980 0.05 0.4 1.5 3345 0.02 0.2 1.0 12mm 3850 0.1 0.84 2.4 3320 0.05 0.5 1.8 2790 0.02 0.2 1.2 16mm 2885 0.15 1.12 3.2 2485 0.075 0.64 2.4 2090 0.03 0.3 1.6 20mm 2300 0.2 1.4 4.0 2000 0.1 0.8 3.0 1670 0.04 0.4 2.0 ■ How to set cutting conditions on different overhang length The recommended cutting condition is depended by the L/D factor. L/D ratio table : EX : Tool : Ød=12mm Square Head L/D VC (m/min) fz (mm/t) ae (mm) Overhang length : 50mm L/D : 50/12 = 4.16 2~3 100% 100% 100% Material HRC : 35 ~ 45 Application : Shoulder Milling 4~5 70% 80% 50% Cutting condition is recommended as : 6~7 50% 70% 30% Vc = 120*70% = 84 m/min fz = 0.05*80% = 0.04 mm/t 8~9 40% 60% 20% ap = 9.6 mm max ae = 2.4*50% = 1.2 mm A407

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020