Основной каталог Winstar 2021 - страница 268

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

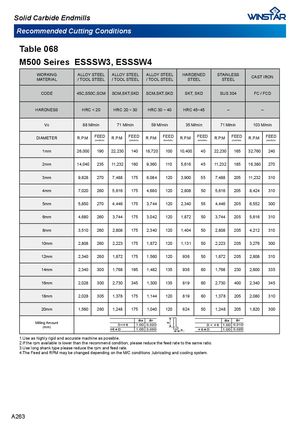

Solid Carbide Endmills Recommended Cutting Conditions Table 068 M500 Seires ESSSW3, ESSSW4 WORKINGMATERIAL ALLOY STEEL ALLOY STEEL ALLOY STEEL HARDENED/ TOOL STEEL/ TOOL STEEL/ TOOL STEELSTEELSTAINLESSSTEELCAST IRON CODE 45C,S50C,SCM SCM,SKT,SKD SCM,SKT,SKD SKT, SKD SUS 304 FC / FCD HARDNESS HRC < 20 HRC 20 ~ 30 HRC 30 ~ 40 HRC 45~45 ‒ ‒ Vc 88 M/min 71 M/min 59 M/min 35 M/min 71 M/min 103 M/min DIAMETER R.P.M FEED R.P.M FEED R.P.M FEED R.P.M FEED R.P.M FEED R.P.M FEED (mm/min) (mm/min) (mm/min) (mm/min) (mm/min) (mm/min) 1mm 26,000 190 22,230 140 18,720 100 10,400 40 22,230 165 32,760 240 2mm 14,040 235 11,232 160 9,360 110 5,616 45 11,232 185 16,380 270 3mm 9,828 270 7,488 175 6,084 120 3,900 55 7,488 205 11,232 310 4mm 7,020 260 5,616 175 4,680 120 2,808 50 5,616 205 8,424 310 5mm 5,850 270 4,446 175 3,744 120 2,340 55 4,446 205 6,552 300 6mm 4,680 260 3,744 175 3,042 120 1,872 50 3,744 205 5,616 310 8mm 3,510 260 2,808 175 2,340 120 1,404 50 2,808 205 4,212 310 10mm 2,808 260 2,223 175 1,872 120 1,131 50 2,223 205 3,276 300 12mm 2,340 260 1,872 175 1,560 120 936 50 1,872 205 2,808 310 14mm 2,340 300 1,768 195 1,482 135 936 60 1,768 230 2,600 335 16mm 2,028 300 2,730 345 1,300 135 819 60 2,730 400 2,340 345 18mm 2,028 305 1,378 175 1,144 120 819 60 1,378 205 2,080 310 20mm 1,560 260 1,248 175 1,040 120 624 50 1,248 205 1,820 300 Milling Amount (mm) 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. A263

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020