Основной каталог Winstar 2021 - страница 256

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

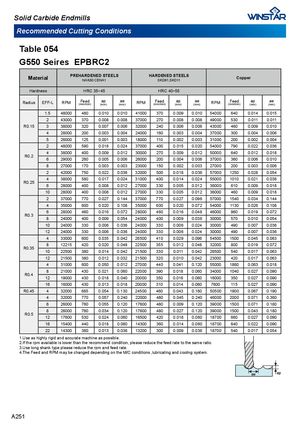

Solid Carbide Endmills Recommended Cutting Conditions Table 054 G550 Seires EPBRC2 Material PREHARDENED STEELSNAK80 CENA1 HARDENED STEELSSKD61,SKD11 Copper Hardness HRC 35~45 HRC 40~55 Radius EFF-L RPM Feed (mm/min) ap(mm) ae(mm) RPM Feed (mm/min) ap(mm) ae (mm) RPM Feed (mm/min) ap(mm) ae (mm) 1.5 48000 480 0.010 0.010 41000 370 0.009 0.010 54000 640 0.014 0.015 2 43000 370 0.008 0.008 37000 270 0.008 0.008 49000 530 0.011 0.011 R0.15 3 38000 320 0.007 0.006 32000 240 0.006 0.006 43000 460 0.009 0.010 4 28000 200 0.003 0.004 24000 160 0.003 0.004 37000 300 0.004 0.006 5 26000 125 0.001 0.003 18000 110 0.002 0.003 31000 200 0.002 0.004 2 48000 590 0.018 0.024 37000 400 0.015 0.020 54000 790 0.022 0.036 4 38000 400 0.009 0.012 30000 270 0.009 0.012 50000 640 0.012 0.018 R0.2 6 29000 260 0.005 0.006 26000 200 0.004 0.006 37000 360 0.006 0.010 8 27000 170 0.003 0.003 23000 150 0.002 0.003 27000 200 0.003 0.006 2 42000 750 0.022 0.036 32000 500 0.018 0.036 57000 1250 0.028 0.054 4 38000 580 0.017 0.024 31000 400 0.014 0.024 55000 1010 0.021 0.036 R0.25 6 28000 400 0.008 0.012 27000 330 0.005 0.012 36000 610 0.009 0.018 10 28000 400 0.008 0.012 27000 330 0.005 0.012 36000 460 0.009 0.018 2 37000 770 0.027 0.144 37000 770 0.027 0.096 57000 1540 0.034 0.144 4 35000 600 0.020 0.108 35000 600 0.020 0.072 54000 1130 0.026 0.108 6 28000 460 0.016 0.072 28000 460 0.016 0.048 46000 960 0.019 0.072 R0.3 8 24000 400 0.009 0.054 24000 400 0.009 0.036 30000 570 0.010 0.054 10 24000 330 0.006 0.036 24000 330 0.006 0.024 30000 490 0.007 0.036 12 24000 330 0.006 0.036 24000 330 0.006 0.024 30000 490 0.007 0.036 4 33000 600 0.035 0.042 26500 410 0.029 0.096 54500 1500 0.045 0.063 8 12215 420 0.020 0.048 22500 355 0.012 0.048 32000 800 0.019 0.072 R0.35 10 22500 380 0.014 0.042 21500 330 0.011 0.042 26500 540 0.017 0.063 12 21500 380 0.012 0.032 21500 320 0.010 0.042 23000 420 0.017 0.063 4 31000 600 0.050 0.012 27000 440 0.041 0.120 55000 1860 0.063 0.018 8 21000 430 0.021 0.060 22000 390 0.018 0.060 34000 1040 0.027 0.090 R0.4 12 19000 430 0.018 0.040 20000 350 0.016 0.060 16000 350 0.027 0.090 16 16000 430 0.013 0.018 20000 310 0.014 0.060 7600 115 0.027 0.090 R0.45 4 32000 685 0.054 0.130 24500 460 0.043 0.180 50500 1900 0.067 0.190 4 32000 770 0.057 0.240 22000 480 0.045 0.240 46000 2000 0.071 0.360 6 26000 760 0.055 0.120 17600 480 0.009 0.120 39000 1500 0.071 0.180 8 26000 760 0.034 0.120 17600 480 0.027 0.120 39000 1500 0.043 0.180 R0.5 12 17600 530 0.024 0.060 16500 420 0.018 0.060 18700 660 0.027 0.090 16 15400 440 0.018 0.060 14300 360 0.014 0.060 18700 640 0.022 0.090 22 14300 360 0.013 0.036 13200 300 0.009 0.036 18700 540 0.017 0.054 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. A251

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020