Основной каталог Winstar 2021 - страница 250

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

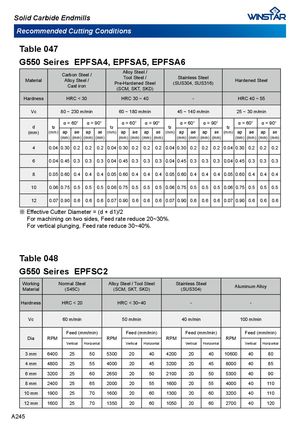

Solid Carbide Endmills Recommended Cutting Conditions Table 047 G550 Seires EPFSA4, EPFSA5, EPFSA6 Carbon Steel /MaterialAlloy Steel /Cast ironAlloy Steel /Tool Steel / Stainless SteelPre-Hardened Steel(SUS304, SUS316)Hardened Steel(SCM, SKT, SKD) Hardness HRC < 30 HRC 30 ~ 40 - HRC 40 ~ 55 Vc 80 ~ 230 m/min 60 ~ 180 m/min 45 ~ 140 m/min 25 ~ 30 m/min α = 60° α = 90° α = 60° α = 90° α = 60° α = 90° α = 60° α = 90° d fz fz fz fz (mm) (mm) ap ae ap ae (mm) ap ae ap ae (mm) ap ae ap ae (mm) ap ae ap ae (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) 4 0.04 0.30 0.2 0.2 0.2 0.04 0.30 0.2 0.2 0.2 0.04 0.30 0.2 0.2 0.2 0.04 0.30 0.2 0.2 0.2 6 0.04 0.45 0.3 0.3 0.3 0.04 0.45 0.3 0.3 0.3 0.04 0.45 0.3 0.3 0.3 0.04 0.45 0.3 0.3 0.3 8 0.05 0.60 0.4 0.4 0.4 0.05 0.60 0.4 0.4 0.4 0.05 0.60 0.4 0.4 0.4 0.05 0.60 0.4 0.4 0.4 10 0.06 0.75 0.5 0.5 0.5 0.06 0.75 0.5 0.5 0.5 0.06 0.75 0.5 0.5 0.5 0.06 0.75 0.5 0.5 0.5 12 0.07 0.90 0.6 0.6 0.6 0.07 0.90 0.6 0.6 0.6 0.07 0.90 0.6 0.6 0.6 0.07 0.90 0.6 0.6 0.6 ※ Effective Cutter Diameter = (d + d1)/2 For machining on two sides, Feed rate reduce 20~30%. For vertical plunging, Feed rate reduce 30~40%. Table 048 G550 Seires EPFSC2 Working Normal Steel Alloy Steel / Tool Steel Stainless SteelMaterial(S45C)(SCM, SKT, SKD)(SUS304)Aluminum Alloy Hardness HRC < 20 HRC < 30~40 - - Vc 60 m/min 50 m/min 40 m/min 100 m/min Feed (mm/min) Feed (mm/min) Feed (mm/min) Feed (mm/min) Dia RPM RPM RPM RPM Vertical Horizontal Vertical Horizontal Vertical Horizontal Vertical Horizontal 3 mm 6400 25 50 5300 20 40 4200 20 40 10600 40 80 4 mm 4800 25 55 4000 20 45 3200 20 45 8000 40 85 6 mm 3200 25 60 2650 20 50 2100 20 50 5300 40 90 8 mm 2400 25 65 2000 20 55 1600 20 55 4000 40 110 10 mm 1900 25 70 1600 20 60 1300 20 60 3200 40 110 12 mm 1600 25 70 1350 20 60 1050 20 60 2700 40 120 A245

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020