Основной каталог Winstar 2021 - страница 235

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

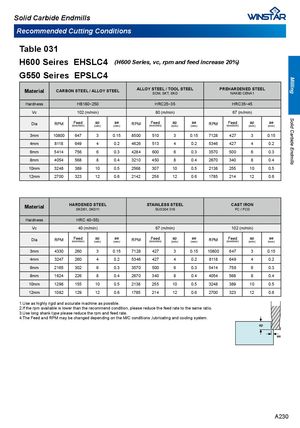

Solid Carbide EndmillsMilling Solid Carbide Endmills Recommended Cutting Conditions Table 031 H600 Seires EHSLC4 (H600 Series, vc, rpm and feed increase 20%) G550 Seires EPSLC4 Material CARBON STEEL / ALLOY STEEL ALLOY STEEL / TOOL STEELSCM, SKT, SKD PREHARDENED STEELNAK80 CENA1 Hardness HB180~250 HRC25~35 HRC35~45 Vc 102 (m/min) 80 (m/min) 67 (m/min) Dia RPM Feed (mm/min) ap (mm) ae(mm) RPM Feed (mm/min) ap(mm) ae(mm) RPM Feed (mm/min) ap(mm) ae(mm) 3mm 10800 647 3 0.15 8500 510 3 0.15 7128 427 3 0.15 4mm 8118 649 4 0.2 4626 513 4 0.2 5346 427 4 0.2 6mm 5414 756 6 0.3 4284 600 6 0.3 3570 500 6 0.3 8mm 4054 568 8 0.4 3210 450 8 0.4 2670 340 8 0.4 10mm 3248 389 10 0.5 2568 307 10 0.5 2138 255 10 0.5 12mm 2700 323 12 0.6 2142 256 12 0.6 1785 214 12 0.6 Material HARDENED STEELSKD61, SKD11 STAINLESS STEELSUS304 316 CAST IRONFC / FCD Hardness HRC 40~55) Vc 40 (m/min) 67 (m/min) 102 (m/min) Dia RPM Feed (mm/min) ap (mm) ae(mm) RPM Feed (mm/min) ap(mm) ae(mm) RPM Feed (mm/min) ap(mm) ae(mm) 3mm 4330 260 3 0.15 7128 427 3 0.15 10800 647 3 0.15 4mm 3247 260 4 0.2 5346 427 4 0.2 8118 649 4 0.2 6mm 2165 302 6 0.3 3570 500 6 0.3 5414 756 6 0.3 8mm 1624 226 8 0.4 2670 340 8 0.4 4054 568 8 0.4 10mm 1298 155 10 0.5 2138 255 10 0.5 3248 389 10 0.5 12mm 1082 129 12 0.6 1785 214 12 0.6 2700 323 12 0.6 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. A230

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020