Основной каталог Winstar 2021 - страница 228

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

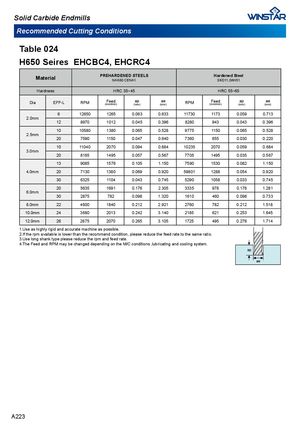

Solid Carbide Endmills Recommended Cutting Conditions Table 024 H650 Seires EHCBC4, EHCRC4 Material PREHARDENED STEELSNAK80 CENA1 Hardened SteelSKD11,SKH51 Hardness HRC 35~45 HRC 55~65 Dia EFF-L RPM Feed (mm/min) ap (mm) ae (mm) RPM Feed (mm/min) ap (mm) ae (mm) 6 12650 1265 0.063 0.633 11730 1173 0.059 0.713 2.0mm 12 8970 1012 0.045 0.396 8280 943 0.043 0.396 10 10580 1380 0.065 0.528 9775 1150 0.065 0.528 2.5mm 20 7590 1150 0.047 0.640 7360 655 0.030 0.220 10 11040 2070 0.094 0.684 10235 2070 0.059 0.684 3.0mm 20 8165 1495 0.057 0.567 7705 1495 0.035 0.567 13 9085 1576 0.105 1.150 7590 1530 0.082 1.150 4.0mm 20 7130 1380 0.069 0.920 59801 1288 0.054 0.920 30 6325 1104 0.043 0.745 5290 1058 0.033 0.745 20 5635 1691 0.176 2.305 3335 978 0.176 1.281 6.0mm 30 2875 782 0.098 1.320 1610 460 0.098 0.733 8.0mm 22 4600 1840 0.212 2.921 2760 782 0.212 1.518 10.0mm 24 3680 2013 0.242 3.140 2185 621 0.253 1.645 12.0mm 26 2875 2070 0.265 3.105 1725 495 0.276 1.714 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. A223

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020