Общий каталог Winstar 2015 - 2016 - страница 86

Навигация

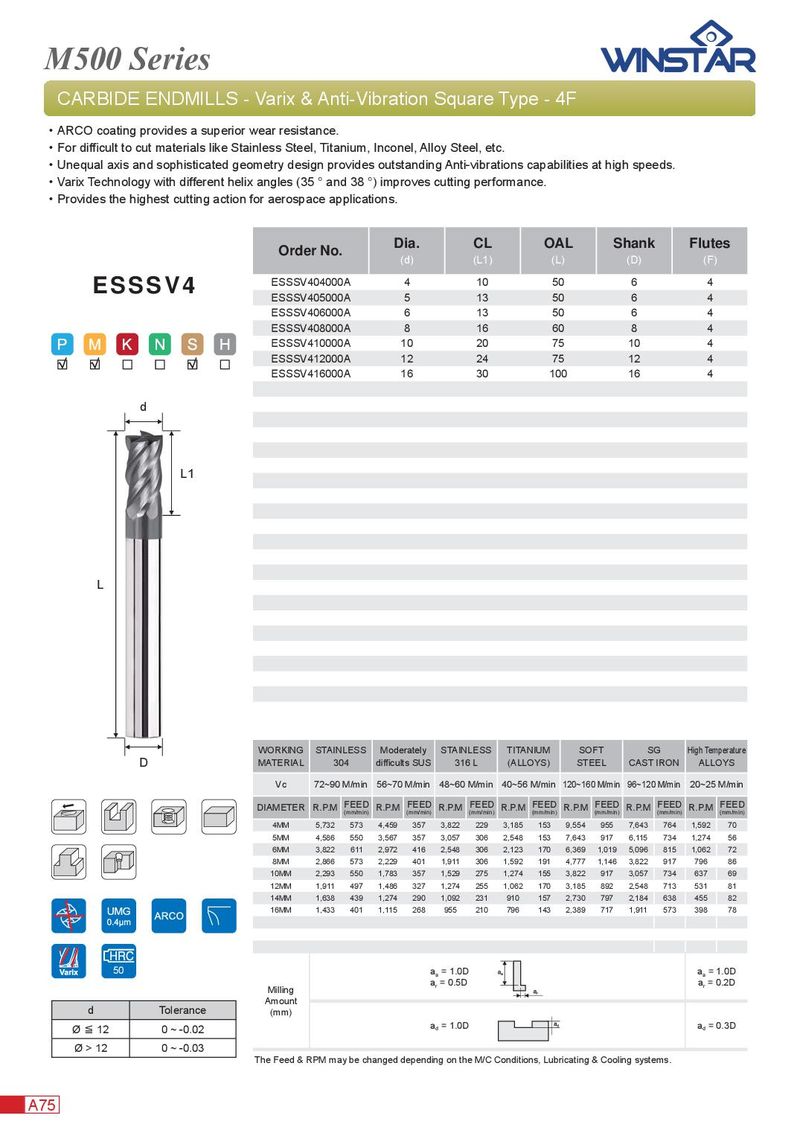

M500 Series CARBIDE ENDMILLS - Varix & Anti-Vibration Square Type - 4F . ARCO coating provides a superior wear resistance. . For diffi cult to cut materials like Stainless Steel, Titanium, Inconel, Alloy Steel, etc. . Unequal axis and sophisticated geometry design provides outstanding Anti-vibrations capabilities at high speeds. . Varix Technology with different helix angles (35 ° and 38 °) improves cutting performance. . Provides the highest cutting action for aerospace applications. Dia. CL OAL Shank Flutes Order No. (d) (L1) (L) (D) (F) ESSSV404000A 4 10 50 6 4 ESSSV4 ESSSV405000A 5 13 50 6 4 ESSSV406000A 6 13 50 6 4 ESSSV408000A 8 16 60 8 4 ESSSV410000A 10 20 75 10 4 ESSSV412000A 12 24 75 12 4 ESSSV416000A 16 30 100 16 4 d L1 L WORKING STAINLESS Moderately STAINLESS TITANIUM SOFT SG High Temperature D MATERIAL 304 difficults SUS 316 L (ALLOYS) STEEL CAST IRON ALLOYS Vc 72~90 M/min 56~70 M/min 48~60 M/min 40~56 M/min 120~160 M/min 96~120 M/min 20~25 M/min DIAMETER R.P.M FEED (mm/min) R.P.M FEED FEED FEED (mm/min) R.P.M (mm/min) R.P.M FEED (mm/min) R.P.M (mm/min) R.P.M FEED (mm/min) R.P.M FEED (mm/min) 4MM 5,732 573 4,459 357 3,822 229 3,185 153 9,554 955 7,643 764 1,592 70 5MM 4,586 550 3,567 357 3,057 306 2,548 153 7,643 917 6,115 734 1,274 56 6MM 3,822 611 2,972 416 2,548 306 2,123 170 6,369 1,019 5,096 815 1,062 72 8MM 2,866 573 2,229 401 1,911 306 1,592 191 4,777 1,146 3,822 917 796 86 10MM 2,293 550 1,783 357 1,529 275 1,274 155 3,822 917 3,057 734 637 69 12MM 1,911 497 1,486 327 1,274 255 1,062 170 3,185 892 2,548 713 531 81 14MM 1,638 439 1,274 290 1,092 231 910 157 2,730 797 2,184 638 455 82 16MM 1,433 401 1,115 268 955 210 796 143 2,389 717 1,911 573 398 78 50 a a = 1.0D a a = 1.0D a r = 0.5D a r = 0.2D Milling Amount d Tolerance (mm) Ø ≦ 12 0 ~ -0.02 a d = 1.0D a d = 0.3D Ø > 12 0 ~ -0.03 The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A75

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021