Общий каталог Winstar 2015 - 2016 - страница 75

Навигация

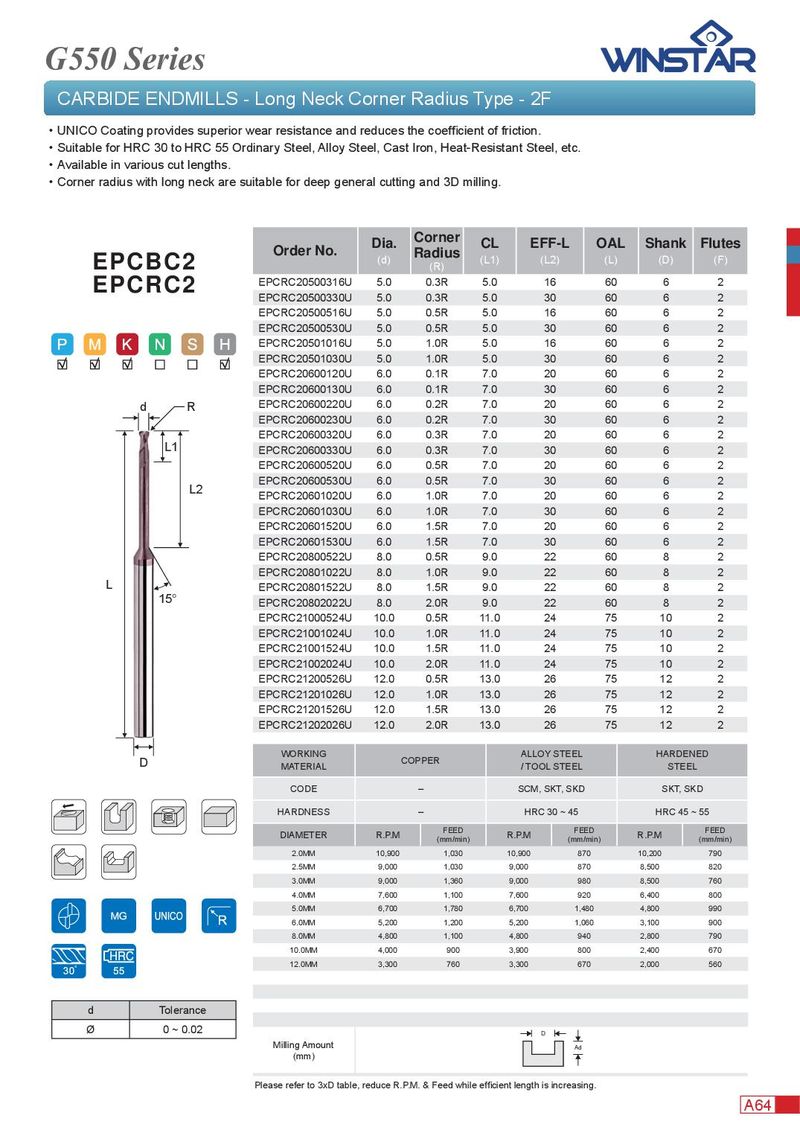

G550 Series CARBIDE ENDMILLS - Long Neck Corner Radius Type - 2F . UNICO Coating provides superior wear resistance and reduces the coeffi cient of friction. . Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc. . Available in various cut lengths. . Corner radius with long neck are suitable for deep general cutting and 3D milling. Corner Dia. CL EFF-L OAL Shank Flutes Order No. Radius (d) (L1) (L2) (L) (D) (F) EPCBC2 (R) EPCRC20500316U 5.0 0.3R 5.0 16 60 6 2 EPCRC2 EPCRC20500330U 5.0 0.3R 5.0 30 60 6 2 EPCRC20500516U 5.0 0.5R 5.0 16 60 6 2 EPCRC20500530U 5.0 0.5R 5.0 30 60 6 2 EPCRC20501016U 5.0 1.0R 5.0 16 60 6 2 EPCRC20501030U 5.0 1.0R 5.0 30 60 6 2 EPCRC20600120U 6.0 0.1R 7.0 20 60 6 2 EPCRC20600130U 6.0 0.1R 7.0 30 60 6 2 d R EPCRC20600220U 6.0 0.2R 7.0 20 60 6 2 EPCRC20600230U 6.0 0.2R 7.0 30 60 6 2 EPCRC20600320U 6.0 0.3R 7.0 20 60 6 2 L1 EPCRC20600330U 6.0 0.3R 7.0 30 60 6 2 EPCRC20600520U 6.0 0.5R 7.0 20 60 6 2 EPCRC20600530U 6.0 0.5R 7.0 30 60 6 2 L2 EPCRC20601020U 6.0 1.0R 7.0 20 60 6 2 EPCRC20601030U 6.0 1.0R 7.0 30 60 6 2 EPCRC20601520U 6.0 1.5R 7.0 20 60 6 2 EPCRC20601530U 6.0 1.5R 7.0 30 60 6 2 EPCRC20800522U 8.0 0.5R 9.0 22 60 8 2 EPCRC20801022U 8.0 1.0R 9.0 22 60 8 2 L EPCRC20801522U 8.0 1.5R 9.0 22 60 8 2 15° EPCRC20802022U 8.0 2.0R 9.0 22 60 8 2 EPCRC21000524U 10.0 0.5R 11.0 24 75 10 2 EPCRC21001024U 10.0 1.0R 11.0 24 75 10 2 EPCRC21001524U 10.0 1.5R 11.0 24 75 10 2 EPCRC21002024U 10.0 2.0R 11.0 24 75 10 2 EPCRC21200526U 12.0 0.5R 13.0 26 75 12 2 EPCRC21201026U 12.0 1.0R 13.0 26 75 12 2 EPCRC21201526U 12.0 1.5R 13.0 26 75 12 2 EPCRC21202026U 12.0 2.0R 13.0 26 75 12 2 WORKING ALLOY STEEL HARDENED D COPPER MATERIAL / TOOL STEEL STEEL CODE ‒ SCM, SKT, SKD SKT, SKD HARDNESS ‒ HRC 30 ~ 45 HRC 45 ~ 55 FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 2.0MM 10,900 1,030 10,900 870 10,200 790 2.5MM 9,000 1,030 9,000 870 8,500 820 3.0MM 9,000 1,360 9,000 980 8,500 760 4.0MM 7,600 1,100 7,600 920 6,400 800 5.0MM 6,700 1,780 6,700 1,480 4,800 990 6.0MM 5,200 1,200 5,200 1,060 3,100 900 8.0MM 4,800 1,100 4,800 940 2,800 790 10.0MM 4,000 900 3,900 800 2,400 670 12.0MM 3,300 760 3,300 670 2,000 560 d Tolerance Ø 0 ~ 0.02 D Milling Amount Ad (mm) Please refer to 3xD table, reduce R.P.M. & Feed while effi cient length is increasing. A64

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021