Общий каталог Winstar 2015 - 2016 - страница 69

Навигация

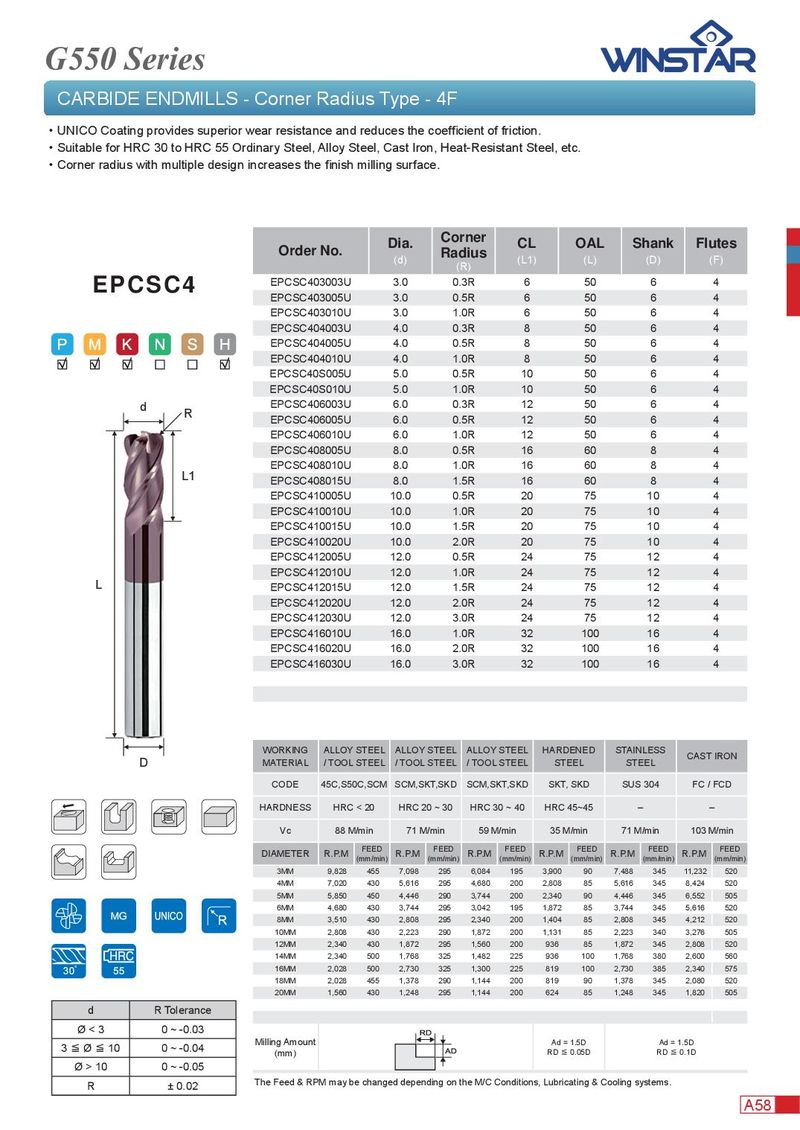

G550 Series CARBIDE ENDMILLS - Corner Radius Type - 4F . UNICO Coating provides superior wear resistance and reduces the coeffi cient of friction. . Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc. . Corner radius with multiple design increases the fi nish milling surface. Corner Dia. CL OAL Shank Flutes Order No. Radius (d) (L1) (L) (D) (F) (R) EPCSC403003U 3.0 0.3R 6 50 6 4 EPCSC4 EPCSC403005U 3.0 0.5R 6 50 6 4 EPCSC403010U 3.0 1.0R 6 50 6 4 EPCSC404003U 4.0 0.3R 8 50 6 4 EPCSC404005U 4.0 0.5R 8 50 6 4 EPCSC404010U 4.0 1.0R 8 50 6 4 EPCSC40S005U 5.0 0.5R 10 50 6 4 EPCSC40S010U 5.0 1.0R 10 50 6 4 d EPCSC406003U 6.0 0.3R 12 50 6 4 R EPCSC406005U 6.0 0.5R 12 50 6 4 EPCSC406010U 6.0 1.0R 12 50 6 4 EPCSC408005U 8.0 0.5R 16 60 8 4 EPCSC408010U 8.0 1.0R 16 60 8 4 L1 EPCSC408015U 8.0 1.5R 16 60 8 4 EPCSC410005U 10.0 0.5R 20 75 10 4 EPCSC410010U 10.0 1.0R 20 75 10 4 EPCSC410015U 10.0 1.5R 20 75 10 4 EPCSC410020U 10.0 2.0R 20 75 10 4 EPCSC412005U 12.0 0.5R 24 75 12 4 EPCSC412010U 12.0 1.0R 24 75 12 4 L EPCSC412015U 12.0 1.5R 24 75 12 4 EPCSC412020U 12.0 2.0R 24 75 12 4 EPCSC412030U 12.0 3.0R 24 75 12 4 EPCSC416010U 16.0 1.0R 32 100 16 4 EPCSC416020U 16.0 2.0R 32 100 16 4 EPCSC416030U 16.0 3.0R 32 100 16 4 WORKING ALLOY STEEL ALLOY STEEL ALLOY STEEL HARDENED STAINLESS CAST IRON D MATERIAL / TOOL STEEL / TOOL STEEL / TOOL STEEL STEEL STEEL CODE 45C,S50C,SCM SCM,SKT,SKD SCM,SKT,SKD SKT, SKD SUS 304 FC / FCD HARDNESS HRC < 20 HRC 20 ~ 30 HRC 30 ~ 40 HRC 45~45 ‒ ‒ Vc 88 M/min 71 M/min 59 M/min 35 M/min 71 M/min 103 M/min FEED FEED FEED FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 3MM 9,828 455 7,098 295 6,084 195 3,900 90 7,488 345 11,232 520 4MM 7,020 430 5,616 295 4,680 200 2,808 85 5,616 345 8,424 520 5MM 5,850 450 4,446 290 3,744 200 2,340 90 4,446 345 6,552 505 6MM 4,680 430 3,744 295 3,042 195 1,872 85 3,744 345 5,616 520 8MM 3,510 430 2,808 295 2,340 200 1,404 85 2,808 345 4,212 520 10MM 2,808 430 2,223 290 1,872 200 1,131 85 2,223 340 3,276 505 12MM 2,340 430 1,872 295 1,560 200 936 85 1,872 345 2,808 520 14MM 2,340 500 1,768 325 1,482 225 936 100 1,768 380 2,600 560 16MM 2,028 500 2,730 325 1,300 225 819 100 2,730 385 2,340 575 18MM 2,028 455 1,378 290 1,144 200 819 90 1,378 345 2,080 520 20MM 1,560 430 1,248 295 1,144 200 624 85 1,248 345 1,820 505 d R Tolerance Ø < 3 0 ~ -0.03 Milling Amount Ad = 1.5D Ad = 1.5D 3 ≦ Ø ≦ 10 0 ~ -0.04 (mm) RD ≦ 0.05D RD ≦ 0.1D Ø > 10 0 ~ -0.05 R ± 0.02 The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A58

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021