Общий каталог Winstar 2015 - 2016 - страница 23

Навигация

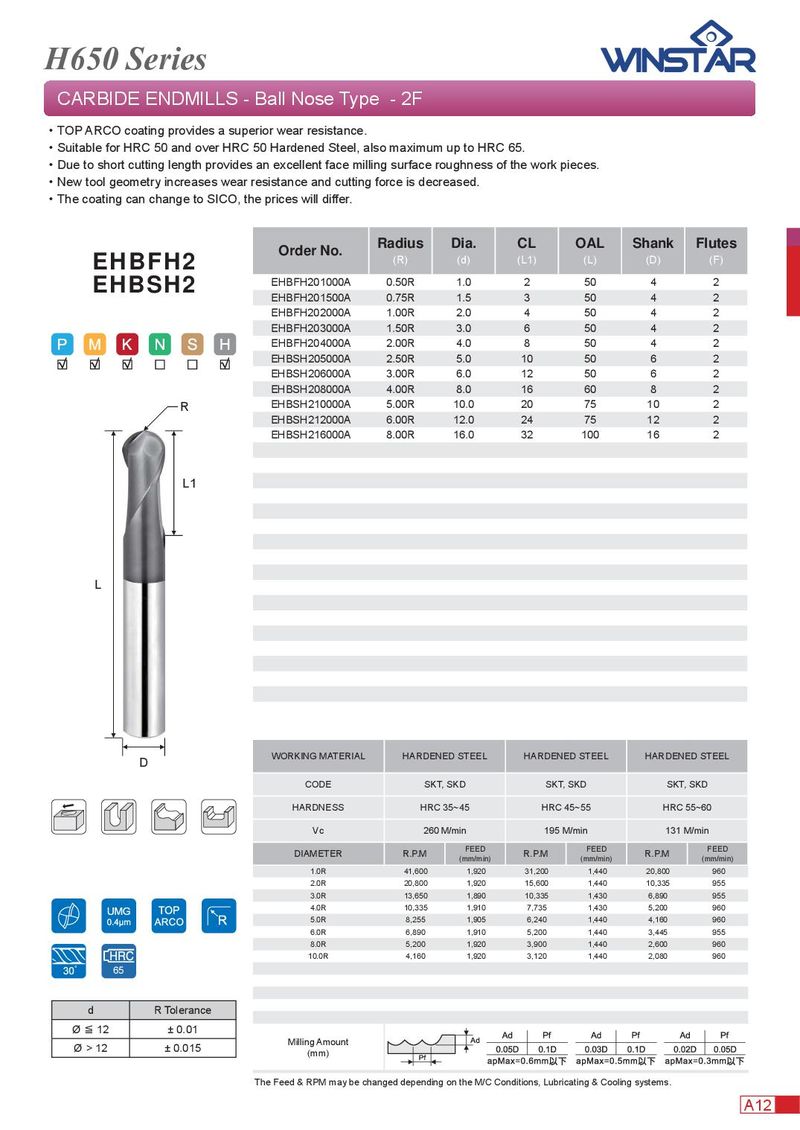

H650 Series CARBIDE ENDMILLS - Ball Nose Type - 2F . TOP ARCO coating provides a superior wear resistance. . Suitable for HRC 50 and over HRC 50 Hardened Steel, also maximum up to HRC 65. . Due to short cutting length provides an excellent face milling surface roughness of the work pieces. . New tool geometry increases wear resistance and cutting force is decreased. . The coating can change to SICO, the prices will differ. Radius Dia. CL OAL Shank Flutes Order No. (R) (d) (L1) (L) (D) (F) EHBFH2 EHBFH201000A 0.50R 1.0 2 50 4 2 EHBSH2 EHBFH201500A 0.75R 1.5 3 50 4 2 EHBFH202000A 1.00R 2.0 4 50 4 2 EHBFH203000A 1.50R 3.0 6 50 4 2 EHBFH204000A 2.00R 4.0 8 50 4 2 EHBSH205000A 2.50R 5.0 10 50 6 2 EHBSH206000A 3.00R 6.0 12 50 6 2 EHBSH208000A 4.00R 8.0 16 60 8 2 R EHBSH210000A 5.00R 10.0 20 75 10 2 EHBSH212000A 6.00R 12.0 24 75 12 2 EHBSH216000A 8.00R 16.0 32 100 16 2 L1 L WORKING MATERIAL HARDENED STEEL HARDENED STEEL HARDENED STEEL D CODE SKT, SKD SKT, SKD SKT, SKD HARDNESS HRC 35~45 HRC 45~55 HRC 55~60 Vc 260 M/min 195 M/min 131 M/min FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 1.0R 41,600 1,920 31,200 1,440 20,800 960 2.0R 20,800 1,920 15,600 1,440 10,335 955 3.0R 13,650 1,890 10,335 1,430 6,890 955 4.0R 10,335 1,910 7,735 1,430 5,200 960 5.0R 8,255 1,905 6,240 1,440 4,160 960 6.0R 6,890 1,910 5,200 1,440 3,445 955 8.0R 5,200 1,920 3,900 1,440 2,600 960 10.0R 4,160 1,920 3,120 1,440 2,080 960 65 d R Tolerance Ø ≦ 12 ± 0.01 Milling Amount Ø > 12 ± 0.015 (mm) The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A12

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021