Общий каталог Winstar 2015 - 2016 - страница 16

Навигация

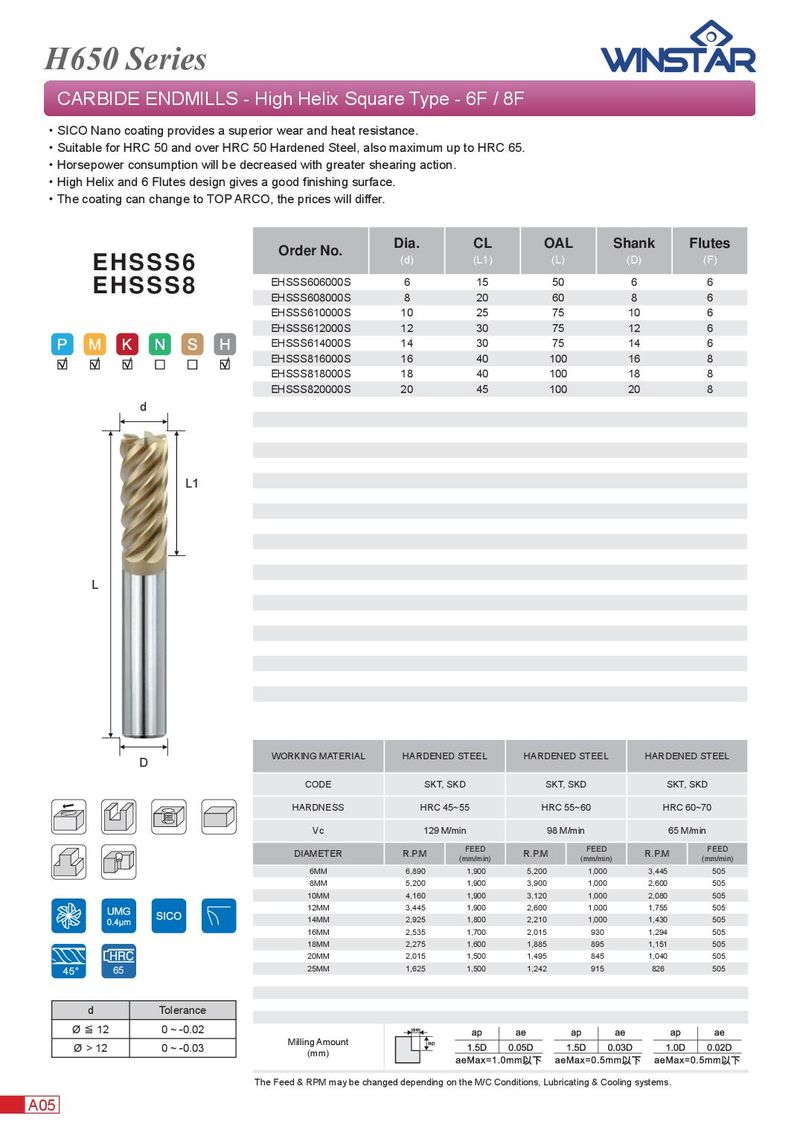

H650 Series CARBIDE ENDMILLS - High Helix Square Type - 6F / 8F . SICO Nano coating provides a superior wear and heat resistance. . Suitable for HRC 50 and over HRC 50 Hardened Steel, also maximum up to HRC 65. . Horsepower consumption will be decreased with greater shearing action. . High Helix and 6 Flutes design gives a good finishing surface. . The coating can change to TOP ARCO, the prices will differ. Dia. CL OAL Shank Flutes Order No. (d) (L1) (L) (D) (F) EHSSS6 EHSSS606000S 6 15 50 6 6 EHSSS8 EHSSS608000S 8 20 60 8 6 EHSSS610000S 10 25 75 10 6 EHSSS612000S 12 30 75 12 6 EHSSS614000S 14 30 75 14 6 EHSSS816000S 16 40 100 16 8 EHSSS818000S 18 40 100 18 8 EHSSS820000S 20 45 100 20 8 d L1 L WORKING MATERIAL HARDENED STEEL HARDENED STEEL HARDENED STEEL D CODE SKT, SKD SKT, SKD SKT, SKD HARDNESS HRC 45~55 HRC 55~60 HRC 60~70 Vc 129 M/min 98 M/min 65 M/min FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 6MM 6,890 1,900 5,200 1,000 3,445 505 8MM 5,200 1,900 3,900 1,000 2,600 505 10MM 4,160 1,900 3,120 1,000 2,080 505 12MM 3,445 1,900 2,600 1,000 1,755 505 14MM 2,925 1,800 2,210 1,000 1,430 505 16MM 2,535 1,700 2,015 930 1,294 505 18MM 2,275 1,600 1,885 895 1,151 505 20MM 2,015 1,500 1,495 845 1,040 505 65 25MM 1,625 1,500 1,242 915 826 505 d Tolerance Ø ≦ 12 0 ~ -0.02 Milling Amount Ø > 12 0 ~ -0.03 (mm) The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A05

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021