Общий каталог Winstar 2015 - 2016 - страница 105

Навигация

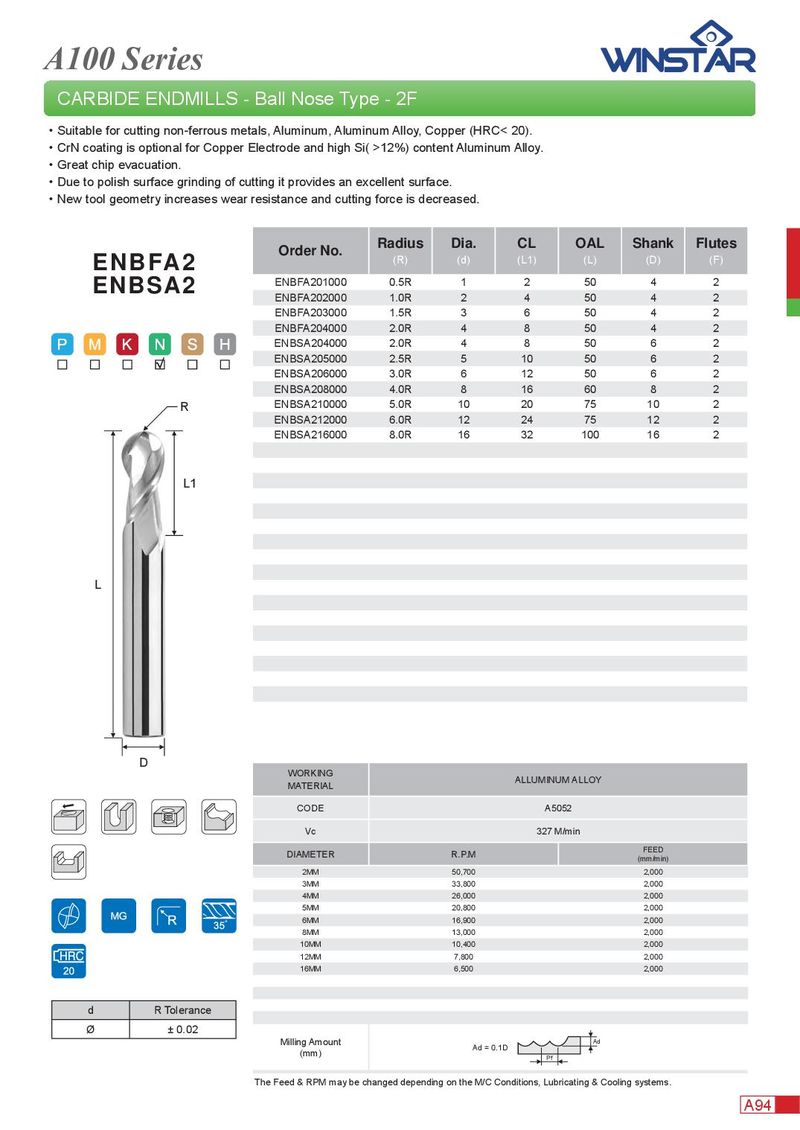

A100 Series CARBIDE ENDMILLS - Ball Nose Type - 2F . Suitable for cutting non-ferrous metals, Aluminum, Aluminum Alloy, Copper (HRC< 20). . CrN coating is optional for Copper Electrode and high Si( >12%) content Aluminum Alloy. . Great chip evacuation. . Due to polish surface grinding of cutting it provides an excellent surface. . New tool geometry increases wear resistance and cutting force is decreased. Radius Dia. CL OAL Shank Flutes Order No. (R) (d) (L1) (L) (D) (F) ENBFA2 ENBFA201000 0.5R 1 2 50 4 2 ENBSA2 ENBFA202000 1.0R 2 4 50 4 2 ENBFA203000 1.5R 3 6 50 4 2 ENBFA204000 2.0R 4 8 50 4 2 ENBSA204000 2.0R 4 8 50 6 2 ENBSA205000 2.5R 5 10 50 6 2 ENBSA206000 3.0R 6 12 50 6 2 ENBSA208000 4.0R 8 16 60 8 2 R ENBSA210000 5.0R 10 20 75 10 2 ENBSA212000 6.0R 12 24 75 12 2 ENBSA216000 8.0R 16 32 100 16 2 L1 L D WORKING ALLUMINUM ALLOY MATERIAL CODE A5052 Vc 327 M/min FEED DIAMETER R.P.M (mm/min) 2MM 50,700 2,000 3MM 33,800 2,000 4MM 26,000 2,000 5MM 20,800 2,000 6MM 16,900 2,000 8MM 13,000 2,000 10MM 10,400 2,000 12MM 7,800 2,000 16MM 6,500 2,000 d R Tolerance Ø ± 0.02 Milling Amount Ad Ad = 0.1D (mm) Pf The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A94

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021