Каталог Winstar сверление - страница 106

Навигация

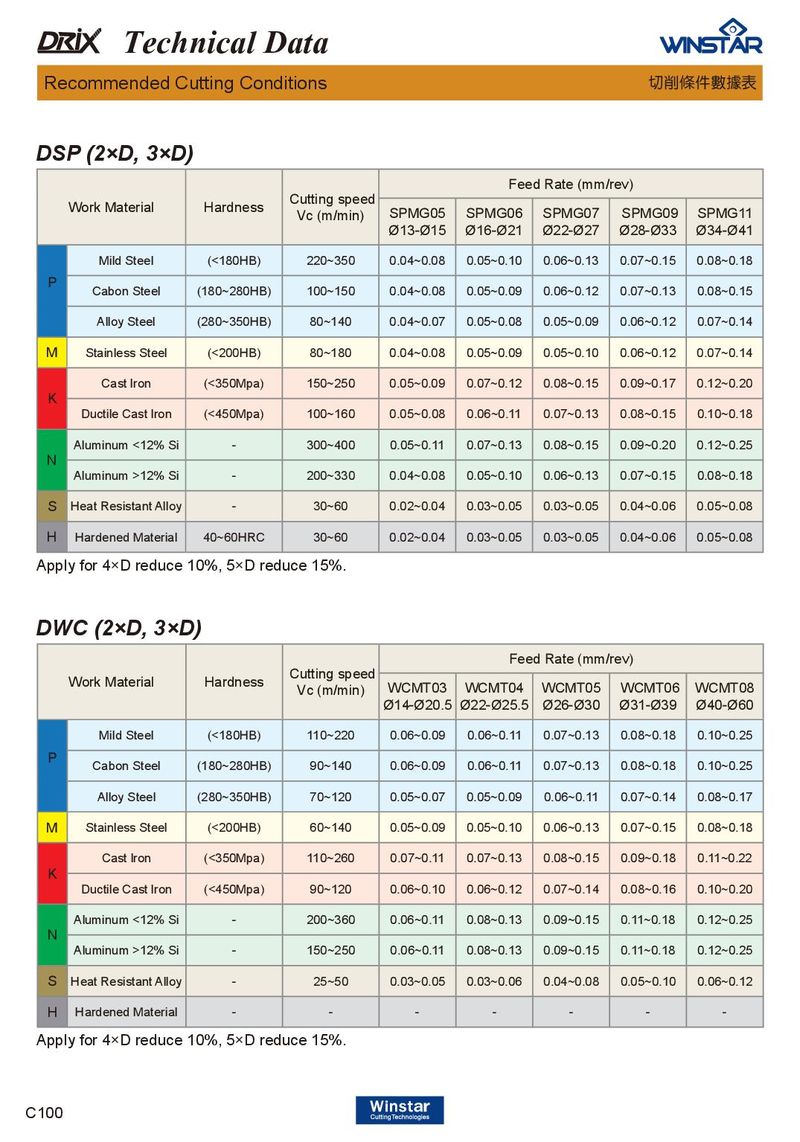

Technical Data Recommended Cutting Conditions 切削條件數據表 DSP (2×D, 3×D) Feed Rate (mm/rev) Cutting speed Work Material Hardness Vc (m/min) SPMG05 SPMG06 SPMG07 SPMG09 SPMG11 Ø13-Ø15 Ø16-Ø21 Ø22-Ø27 Ø28-Ø33 Ø34-Ø41 Mild Steel (<180HB) 220~350 0.04~0.08 0.05~0.10 0.06~0.13 0.07~0.15 0.08~0.18 P Cabon Steel (180~280HB) 100~150 0.04~0.08 0.05~0.09 0.06~0.12 0.07~0.13 0.08~0.15 Alloy Steel (280~350HB) 80~140 0.04~0.07 0.05~0.08 0.05~0.09 0.06~0.12 0.07~0.14 M Stainless Steel (<200HB) 80~180 0.04~0.08 0.05~0.09 0.05~0.10 0.06~0.12 0.07~0.14 Cast lron (<350Mpa) 150~250 0.05~0.09 0.07~0.12 0.08~0.15 0.09~0.17 0.12~0.20 K Ductile Cast lron (<450Mpa) 100~160 0.05~0.08 0.06~0.11 0.07~0.13 0.08~0.15 0.10~0.18 Aluminum <12% Si - 300~400 0.05~0.11 0.07~0.13 0.08~0.15 0.09~0.20 0.12~0.25 N Aluminum >12% Si - 200~330 0.04~0.08 0.05~0.10 0.06~0.13 0.07~0.15 0.08~0.18 S Heat Resistant Alloy - 30~60 0.02~0.04 0.03~0.05 0.03~0.05 0.04~0.06 0.05~0.08 H Hardened Material 40~60HRC 30~60 0.02~0.04 0.03~0.05 0.03~0.05 0.04~0.06 0.05~0.08 Apply for 4×D reduce 10%, 5×D reduce 15%. DWC (2×D, 3×D) Feed Rate (mm/rev) Cutting speed Work Material Hardness Vc (m/min) WCMT03 WCMT04 WCMT05 WCMT06 WCMT08 Ø14-Ø20.5 Ø22-Ø25.5 Ø26-Ø30 Ø31-Ø39 Ø40-Ø60 Mild Steel (<180HB) 110~220 0.06~0.09 0.06~0.11 0.07~0.13 0.08~0.18 0.10~0.25 P Cabon Steel (180~280HB) 90~140 0.06~0.09 0.06~0.11 0.07~0.13 0.08~0.18 0.10~0.25 Alloy Steel (280~350HB) 70~120 0.05~0.07 0.05~0.09 0.06~0.11 0.07~0.14 0.08~0.17 M Stainless Steel (<200HB) 60~140 0.05~0.09 0.05~0.10 0.06~0.13 0.07~0.15 0.08~0.18 Cast lron (<350Mpa) 110~260 0.07~0.11 0.07~0.13 0.08~0.15 0.09~0.18 0.11~0.22 K Ductile Cast lron (<450Mpa) 90~120 0.06~0.10 0.06~0.12 0.07~0.14 0.08~0.16 0.10~0.20 Aluminum <12% Si - 200~360 0.06~0.11 0.08~0.13 0.09~0.15 0.11~0.18 0.12~0.25 N Aluminum >12% Si - 150~250 0.06~0.11 0.08~0.13 0.09~0.15 0.11~0.18 0.12~0.25 S Heat Resistant Alloy - 25~50 0.03~0.05 0.03~0.06 0.04~0.08 0.05~0.10 0.06~0.12 H Hardened Material - - - - - - - Apply for 4×D reduce 10%, 5×D reduce 15%. C100

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021 Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки