Каталог Carbidex сменные пластины 2020 - страница 5

Навигация

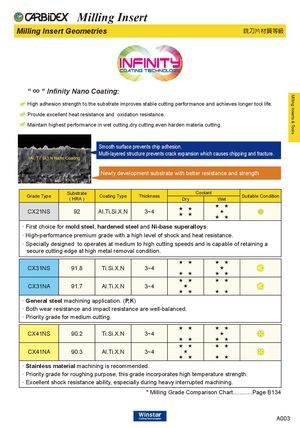

Milling Inserts & Tools Milling Insert Milling Insert Geometries 銑刀片材質等級 “ ∞ “ Infinity Nano Coating: High adhesion strength to the substrate improves stable cutting performance and achieves longer tool life. Provide excellent heat resistance and oxidation resistance. Maintain highest performance in wet cutting,dry cutting,even harden materia cutting. Smooth surface prevents chip adhesion. Multi-layered structure prevents crack expansion which causes chipping and fracture. Newly development substrate with better resistance and strength Grade Type Substrate( HRA )Coating Type Thickness CoolantDryWet Suitable Condition CX21NS 92 Al.Ti.Si.X.N 3~4 ★ ★★ ★ ★ ★★★ ★ .First choice for mold steel, hardened steel and Ni-base superalloys. .High-performance premium grade with a high level of shock and heat resistance. .Specially designed to operates at medium to high cutting speeds and is capable of retaining a secure cutting edge at high metal removal condition. ★ ★ ★ ★ CX31NS 91.8 Ti.Si.X.N 3~4 ★ ★ ★ ★ ★ ★ ★ ★ ★ CX31NA 91.7 Al.Ti.X.N 3~4 ★ ★ ★ ★ ★ .General steel machining application. (P,K) .Both wear resistance and impact resistance are well-balanced. .Priority grade for medium cutting. ★ ★ ★ ★ CX41NS 90.2 Ti.Si.X.N 3~4 ★ ★ ★ ★ ★ ★ ★ ★ ★ CX41NA 90.3 Al.Ti.X.N 3~4 ★ ★ ★ ★ ★ .Stainless material machining is recommended. .Priority grade for roughing purpose, this grade incorporates high temperature strength. .Excellent shock resistance ability, especially during heavy interrupted machining. * Milling Grade Comparison Chart............Page B134 A003

Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Основной каталог Winstar 2021

Основной каталог Winstar 2021 Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020