Каталог Carbidex сменные пластины 2020 - страница 42

Навигация

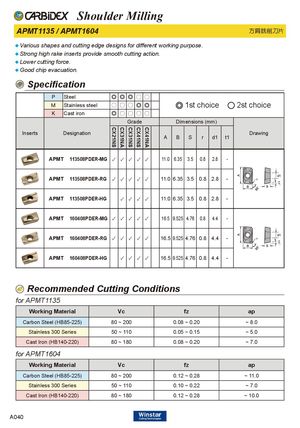

CX21NS CX31NA CX31NS CX41NS CX41NA Shoulder Milling APMT1135 / APMT1604 方肩銑削刀片 ♦ Various shapes and cutting edge designs for different working purpose. ♦ Strong high rake inserts provide smooth cutting action. ♦ Lower cutting force. ♦ Good chip evacuation. Specification P Steel ◎ ◎ ◎ ○ ○ M Stainless steel ○ ○ ○ ◎ ◎ 1st choice 2st choice K Cast iron ◎ ○ ○ ○ ○ Grade Dimensions (mm) Inserts Designation Drawing A B S r d1 t1 APMT 113508PDER-MG ✓ ✓ ✓ ✓ ✓ 11.0 6.35 3.5 0.8 2.8 - APMT 113508PDER-RG ✓ ✓ ✓ ✓ ✓ 11.0 6.35 3.5 0.8 2.8 - APMT 113508PDER-HG ✓ ✓ ✓ ✓ 11.0 6.35 3.5 0.8 2.8 - APMT 160408PDER-MG ✓ ✓ ✓ ✓ ✓ 16.5 9.525 4.76 0.8 4.4 - APMT 160408PDER-RG ✓ ✓ ✓ ✓ ✓ 16.5 9.525 4.76 0.8 4.4 - APMT 160408PDER-HG ✓ ✓ ✓ ✓ 16.5 9.525 4.76 0.8 4.4 - Recommended Cutting Conditions for APMT1135 Working Material Vc fz ap Carbon Steel (HB85-225) 80 ~ 200 0.08 ~ 0.20 ~ 8.0 Stainless 300 Series 50 ~ 110 0.05 ~ 0.15 ~ 5.0 Cast Iron (HB140-220) 80 ~ 180 0.08 ~ 0.20 ~ 7.0 for APMT1604 Working Material Vc fz ap Carbon Steel (HB85-225) 80 ~ 200 0.12 ~ 0.28 ~ 11.0 Stainless 300 Series 50 ~ 110 0.10 ~ 0.22 ~ 7.0 Cast Iron (HB140-220) 80 ~ 180 0.12 ~ 0.28 ~ 10.0 A040

Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Основной каталог Winstar 2021

Основной каталог Winstar 2021 Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020