Общий каталог Widia 2017 - страница 551

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

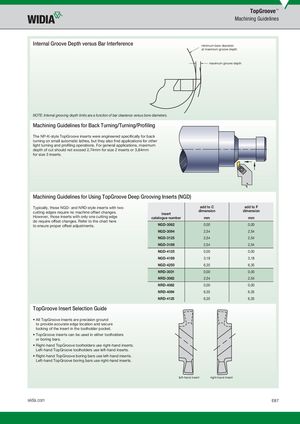

TopGroove™ Machining Guidelines Internal Groove Depth versus Bar Interference minimum bore diameter at maximum groove depth maximum groove depth NOTE: Internal grooving depth limits are a function of bar clearance versus bore diameters. Machining Guidelines for Back Turning/Turning/Profiling The NP-K-style TopGroove inserts were engineered specifically for back turning on small automatic lathes, but they also find applications for other light turning and profiling operations. For general applications, maximum depth of cut should not exceed 2,74mm for size 2 inserts or 3,84mm for size 3 inserts. Machining Guidelines for Using TopGroove Deep Grooving Inserts (NGD) Typically, those NGD- and NRD-style inserts with two add to C add to F cutting edges require no machine offset changes. dimension dimensioninsert However, those inserts with only one cutting edge catalogue number mm mm do require offset changes. Refer to the chart here to ensure proper offset adjustments. NGD-3062 0,00 0,00 NGD-3094 2,54 2,54 NGD-3125 2,54 2,54 NGD-3189 2,54 2,54 NGD-4125 0,00 0,00 NGD-4189 3,18 3,18 NGD-4250 6,35 6,35 NRD-3031 0,00 0,00 NRD-3062 2,54 2,54 NRD-4062 0,00 0,00 NRD-4094 6,35 6,35 NRD-4125 6,35 6,35 TopGroove Insert Selection Guide • All TopGroove inserts are precision ground to provide accurate edge location and secure locking of the insert in the toolholder pocket. • TopGroove inserts can be used in either toolholders or boring bars. • Right-hand TopGroove toolholders use right-hand inserts. Left-hand TopGroove toolholders use left-hand inserts. • Right-hand TopGroove boring bars use left-hand inserts. Left-hand TopGroove boring bars use right-hand inserts. left-hand insert right-hand insert widia.com E87

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020