Общий каталог Widia 2017 - страница 511

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

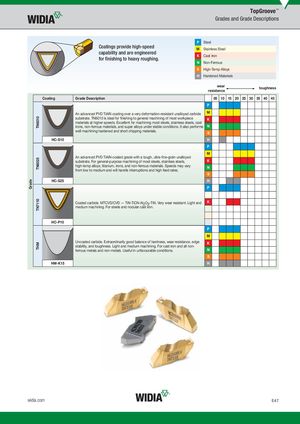

Grade TN6010TN6025TN7110THM TopGroove™ Grades and Grade Descriptions P Steel Coatings provide high-speed M Stainless Steel capability and are engineered for finishing to heavy roughing. K Cast Iron N Non-Ferrous S High-Temp Alloys H Hardened Materials wearresistance toughness Coating Grade Description 05 10 15 20 25 30 35 40 45 P An advanced PVD TiAlN coating over a very deformation-resistant unalloyed carbide M substrate. TN6010 is ideal for finishing to general machining of most workpiece K materials at higher speeds. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs N well machining hardened and short chipping materials. S HC-S10 H P M An advanced PVD TiAlN-coated grade with a tough, ultra-fine-grain unalloyed substrate. For general-purpose machining of most steels, stainless steels, K high-temp alloys, titanium, irons, and non-ferrous materials. Speeds may vary N from low to medium and will handle interruptions and high feed rates. S HC-S25 H P Coated carbide. MTCVD/CVD — TiN-TiCN-Al2O3-TiN. Very wear resistant. Light and K medium machining. For steels and nodular cast iron. HC-P10 P M Uncoated carbide. Extraordinarily good balance of hardness, wear resistance, edge K stability, and toughness. Light and medium machining. For cast iron and all non- ferrous metals and non-metals. Useful in unfavourable conditions. N S HW-K15 H widia.com E47

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020