Общий каталог Widia 2017 - страница 507

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

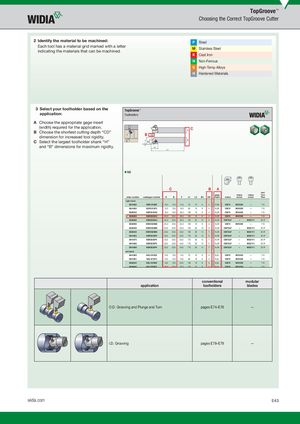

TopGroove™ Choosing the Correct TopGroove Cutter 2 Identify the material to be machined: P Steel Each tool has a material grid marked with a letterindicating the materials that can be machined. M Stainless Steel K Cast Iron N Non-Ferrous S High-Temp Alloys H Hardened Materials 3 Select your toolholder based on the TopGroove™ application: Toolholders A Choose the appropriate gage insert (width) required for the application.BChoose the shortest cutting depth “CD”dimension for increased tool rigidity. B CD H C C Select the largest toolholder shank “H” F B4 B 3° and “B” dimensions for maximum rigidity. L2 L1 n NS C B A hex/ gage clamp clamp Torx order number catalogue number H B F L1 L2 B4 CD insert clamp screw screw Plus right hand 3641682 NSR1010E2 10,0 10,0 14,0 70 19 9 4 N.2R CM74 MS1200 — T10 3641660 NSR1212F2 12,0 12,0 16,0 80 19 9 4 N.2R CM74 MS1200 — T10 3636542 NSR1616H2 16,0 16,0 20,0 100 19 9 4 N.2R CM74 MS1200 — T10 3638589 NSR2020K2 20,0 20,0 25,0 125 19 9 4 N.2R CM74 MS1200 — T10 3638588 NSR2020K3 20,0 20,0 25,0 125 32 13 5 N.3R CM72LP — MS2111 25 IP 3638590 NSR2525M2 25,0 25,0 32,0 150 19 9 4 N.2R CM74 MS1200 — T10 3636536 NSR2525M3 25,0 25,0 32,0 150 32 13 5 N.3R CM72LP — MS2111 25 IP 3636540 NSR2525M4 25,0 25,0 32,0 150 35 14 7 N.4R CM72LP — MS2111 25 IP 3641664 NSR3225P3 32,0 25,0 32,0 170 32 13 5 N.3R CM72LP — MS2111 25 IP 3641675 NSR3225P4 32,0 25,0 32,0 170 35 14 7 N.4R CM72LP — MS2111 25 IP 3641666 NSR3232P3 32,0 32,0 40,0 170 32 13 5 N.3R CM72LP — MS2111 25 IP 3641669 NSR3232P4 32,0 32,0 40,0 170 35 14 7 N.4R CM72LP — MS2111 25 IP left hand 3641683 NSL1010E2 10,0 10,0 14,0 70 19 9 4 N.2L CM75 MS1200 — T10 3641681 NSL1212F2 12,0 12,0 16,0 80 19 9 4 N.2L CM75 MS1200 — T10 3636545 NSL1616H2 16,0 16,0 20,0 100 19 9 4 N.2L CM75 MS1200 — T10 3639045 NSL2020K2 20,0 20,0 25,0 125 19 9 4 N.2L CM75 MS1200 — T10 conventional modular application toolholders blades O.D. Grooving and Plunge and Turn pages E74–E76 — I.D. Grooving pages E78–E79 — widia.com E43

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020