Общий каталог Widia 2017 - страница 470

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

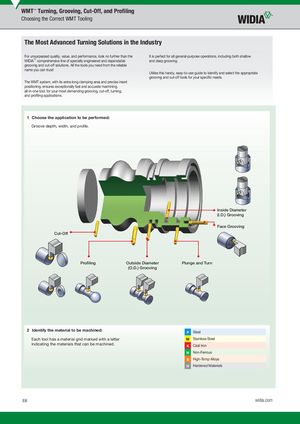

WMT™ Turning, Grooving, Cut-Off, and Profiling Choosing the Correct WMT Tooling The Most Advanced Turning Solutions in the Industry For unsurpassed quality, value, and performance, look no further than the It is perfect for all general-purpose operations, including both shallow WIDIA™ comprehensive line of specially engineered and dependable and deep grooving. grooving and cut-off solutions. All the tools you need from the reliable name you can trust! Utilise this handy, easy-to-use guide to identify and select the appropriate grooving and cut-off tools for your specific needs. The WMT system, with its extra-long clamping area and precise insert positioning, ensures exceptionally fast and accurate machining, all-in-one tool, for your most demanding grooving, cut-off, turning, and profiling applications. 1 Choose the application to be performed: Groove depth, width, and profile. Inside Diameter (I.D.) Grooving Face Grooving Cut-Off Profiling Outside Diameter Plunge and Turn (O.D.) Grooving 2 Identify the material to be machined: P Steel Each tool has a material grid marked with a letter M Stainless Steel indicating the materials that can be machined. K Cast Iron N Non-Ferrous S High-Temp Alloys H Hardened Materials E6 widia.com

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020