Общий каталог Widia 2017 - страница 1786

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

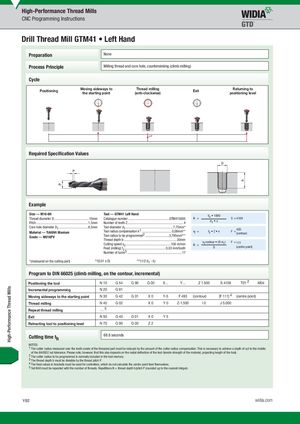

High-Performance Thread Mills CNC Programming Instructions Drill Thread Mill GTM41 • Left Hand Preparation None Process Principle Milling thread and core hole, countersinking (climb milling) Cycle Positioning Moving sideways tothe starting point Thread milling(anti-clockwise) Exit Returning topositioning level Required Specification Values Example Size — M10-6H Tool — GTM41 Left HandThread diameter D.........................................10mmCatalogue number ................................................GTM415005 N = Vc • 1000 S = 4109 Pitch ............................................................. 1,5mm Number of teeth Z..................................................................4 d1 • / Core hole diameter D1 ..................................8,5mmMaterial — TiAl6V4 titaniumGrade — WU16PVTool Tool draiadmiuestceor md1p.e..n.s..a..t.i.o..n...k..1.........................................................................0.7,0,785mmmm***Tool radius to be programmed2 ............................3,795mm***vf =fz • Z • nF = 493 (contour) Thread depth b ..............................................................20mm Cutting speed vc..................................................... 100 m/minFNeuemdb(emrilolifntgu)rnfzs.5.............................................................................................0..,.0..3...m...m.../.t.o..o1t7hN=vf contour • (D-d1)DF = 111(centre point) *(measured on the cutting part) **(0.01 x D) ***(1/2 d1 - k) Program to DIN 66025 (climb milling, on the contour, incremental) Positioning the tool N 10 G 54 G 90 G 00 X… Y… Z 1.500 S 4109 T01 2 M04 Incremental programming N 20 G 91 Moving sideways to the starting point N 30 G 42 G 01 X0 Y-5 F 493 (contour) [F 111] 4 (centre point) Thread milling N 40 G 02 X0 Y0 Z-1.500 I0 J 5.000 Repeat thread milling …5 Exit N 50 G 40 G 01 X0 Y5 Retracting tool to positioning level N 70 G 90 G 00 Z2 Cutting time th 68.8 seconds NOTES: 1 The cutter radius measured over the tooth crests of the threaded part must be reduced by the amount of the cutter radius compensation. This is necessary to achieve a depth of cut to the middle of the 6H/ISO2 nut tolerance. Please note, however, that this also depends on the radial deflection of the tool (tensile strength of the material, projecting length of the tool). 2 The cutter radius to be programmed is normally included in the tool memory. 3 The thread depth b must be divisible by the thread pitch P. 4 The feed values in brackets must be used for controllers, which do not calculate the centre point feed themselves. 5 Set N40 must be repeated with the number of threads. Repetitions N = thread depth b/pitch P (rounded up to the nearest integer). Y82 widia.com High-Performance Thread Mills

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020