Общий каталог Widia 2017 - страница 1682

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

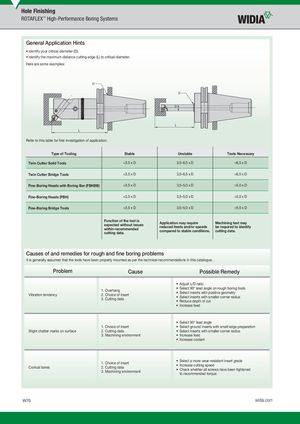

Hole Finishing ROTAFLEX™ High-Performance Boring Systems General Application Hints • Identify your critical diameter (D). • Identify the maximum distance cutting edge (L) to critical diameter. Here are some examples: D D D L L Refer to this table for first investigation of application: Type of Tooling Stable Unstable Tests Necessary Twin Cutter Solid Tools <3,5 x D 3,5–6,5 x D >6,5 x D Twin Cutter Bridge Tools <3,5 x D 3,5–6,5 x D >6,5 x D Fine-Boring Heads with Boring Bar (FBHBB) <3,5 x D 3,5–5,0 x D >5,0 x D Fine-Boring Heads (FBH) <3,5 x D 3,5–5,0 x D >5,0 x D Fine-Boring Bridge Tools <3,5 x D 3,5–5,0 x D >5,0 x D Function of the tool isexpected without issueswithin recommendedcutting data.Application may requireMachining test mayreduced feeds and/or speedsbe required to identifycompared to stable conditions.cutting data. Causes of and remedies for rough and fine boring problems It is generally assumed that the tools have been properly mounted as per the technical recommendations in this catalogue. Problem Cause Possible Remedy • Adjust L/D ratio 1. OverhangVibration tendency2. Choice of insert3. Cutting data• Select 90° lead angle on rough boring tools• Select inserts with positive geometry• Select inserts with smaller corner radius• Reduce depth of cut • Increase feed • Select 90° lead angle 1. Choice of insert • Select ground inserts with small edge preparation Slight chatter marks on surface 2. Cutting data • Select inserts with smaller corner radius 3. Machining environment • Increase feed • Increase coolant Conical bores 1. Choice of insert2. Cutting data3. Machining environment• Select a more wear-resistant insert grade• Increase cutting speed• Check whether all screws have been tightenedto recommended torque W70 widia.com

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020