Общий каталог Widia 2017 - страница 1516

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

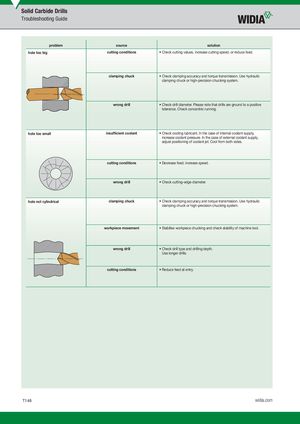

Solid Carbide Drills Troubleshooting Guide problem source solution hole too big cutting conditions • Check cutting values, increase cutting speed, or reduce feed. clamping chuck • Check clamping accuracy and torque transmission. Use hydraulic clamping chuck or high-precision chucking system. wrong drill • Check drill diameter. Please note that drills are ground to a positive tolerance. Check concentric running. hole too small insufficient coolant • Check cooling lubricant. In the case of internal coolant supply, increase coolant pressure. In the case of external coolant supply, adjust positioning of coolant jet. Cool from both sides. cutting conditions • Decrease feed; increase speed. wrong drill • Check cutting-edge diameter. hole not cylindrical clamping chuck • Check clamping accuracy and torque transmission. Use hydraulic clamping chuck or high-precision chucking system. workpiece movement • Stabilise workpiece chucking and check stability of machine tool. wrong drill • Check drill type and drilling depth. Use longer drills. cutting conditions • Reduce feed at entry. T148 widia.com

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020