Общий каталог Widia 2017 - страница 1487

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

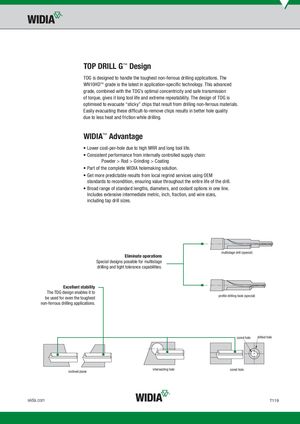

TOP DRILL G™ Design TDG is designed to handle the toughest non-ferrous drilling applications. The WN10HD™ grade is the latest in application-specific technology. This advanced grade, combined with the TDG’s optimal concentricity and safe transmission of torque, gives it long tool life and extreme repeatability. The design of TDG is optimised to evacuate “sticky” chips that result from drilling non-ferrous materials. Easily evacuating these difficult-to-remove chips results in better hole quality due to less heat and friction while drilling. WIDIA™ Advantage • Lower cost-per-hole due to high MRR and long tool life. • Consistent performance from internally controlled supply chain: Powder > Rod > Grinding > Coating • Part of the complete WIDIA holemaking solution. • Get more predictable results from local regrind services using OEM standards to recondition, ensuring value throughout the entire life of the drill. • Broad range of standard lengths, diameters, and coolant options in one line. Includes extensive intermediate metric, inch, fraction, and wire sizes, including tap drill sizes. multistage drill (special) Eliminate operations Special designs possible for multistage drilling and tight tolerance capabilities. Excellent stability The TDG design enables it to be used for even the toughest profile drilling tools (special) non-ferrous drilling applications. cored hole drilled hole inclined plane intersecting hole cored hole widia.com T119

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020