Общий каталог Widia 2017 - страница 1362

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

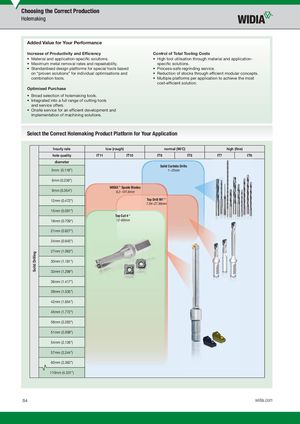

Choosing the Correct Production Holemaking Added Value for Your Performance Increase of Productivity and Efficiency Control of Total Tooling Costs • Material and application-specific solutions. • High tool utilisation through material and application- • Maximum metal removal rates and repeatability. specific solutions. • Standardised design platforms for special tools based • Process-safe regrinding service. on “proven solutions” for individual optimisations and • Reduction of stocks through efficient modular concepts. combination tools. • Multiple platforms per application to achieve the most cost-efficient solution. Optimised Purchase • Broad selection of holemaking tools. • Integrated into a full range of cutting tools and service offers. • Onsite service for an efficient development and implementation of machining solutions. Select the Correct Holemaking Product Platform for Your Application hourly rate low (rough) normal (M/C) high (fine) hole quality IT11 IT10 IT9 IT8 IT7 IT6 diameter Solid Carbide Drills 3mm (0.118") 1–25mm 6mm (0.236") WIDIA™ Spade Blades 9mm (0.354") 9,2–101,6mm 12mm (0.472") Top Drill M1™ 7,94–27,99mm 15mm (0.591") Top Cut 4™ 18mm (0.709") 12–68mm 21mm (0.827") 24mm (0.945") 27mm (1.063") 30mm (1.181") 33mm (1.299") 36mm (1.417") 39mm (1.535") 42mm (1.654") 45mm (1.772") 58mm (2.283") 51mm (2.008") 54mm (2.126") 57mm (2.244") 60mm (2.362") 110mm (4.331") S4 widia.com Solid Drilling

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020