Каталог Tungaloy глубокое сверление 2 - страница 8

Навигация

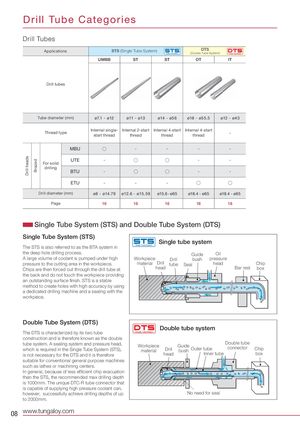

Drill heads Brazed Drill Tu b e Categories Drill Tubes Applications STS (Single Tube System) DTS (Double Tube System) UMBB ST ST OT IT Drill tubes Tube diameter (mm) ø7.1 - ø12 ø11 - ø13 ø14 - ø56 ø18 - ø55.5 ø12 - ø43 Thread type Internal single- Internal 2-start Internal 4-start Internal 4-startstart threadthreadthreadthread- MBU ◯ - - - - UTE - ◯ ◯ - - For solid drilling BTU - ◯ ◯ - - ETU - - - ◯ ◯ Drill diameter (mm) ø8 - ø14.79 ø12.6 - ø15.59 ø15.6 - ø65 ø18.4 - ø65 ø18.4 - ø65 Page 16 16 16 18 18 Single Tube System (STS) and Double Tube System (DTS) Single Tube System (STS) Single tube system The STS is also referred to as the BTA system in the deep hole drilling process. Guide Oil A large volume of coolant is pumped under high Workpiece Drill bush pressure pressure to the cutting area in the workpiece.Chips are then forced out through the drill tube atmaterialDrilltubeheadSealhead ChipBar restbox the back and do not touch the workpiece providing an outstanding surface finish. STS is a stable method to create holes with high accuracy by using a dedicated drilling machine and a sealing with the workpiece. Double Tube System (DTS) Double tube system The DTS is characterized by its two tube construction and is therefore known as the double tube system. A sealing system and pressure head,which is required in the Single Tube System (STS),is not necessary for the DTS and it is thereforeWorkpiecematerialDrillheadGuide bush Outer tube Inner tube Double tube connectorChipbox suitable for conventional general purpose machines such as lathes or machining centers. In general, because of less efficient chip evacuation than the STS, the recommended max drilling depth is 1000mm. The unique DTC-R tube connector that is capable of supplying high pressure coolant can, however, successfully achieve drilling depths of up No need for seal to 2000mm. 08 www.tungaloy.com

Каталог Tungaloy инструмент для автоматов швейцарского типа

Каталог Tungaloy инструмент для автоматов швейцарского типа Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1