Каталог Tungaloy глубокое сверление 2 - страница 24

Навигация

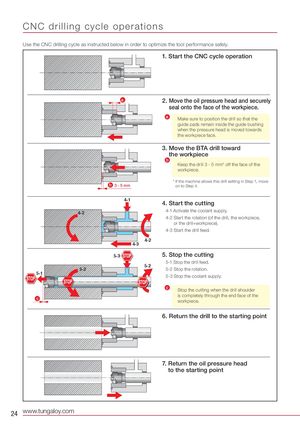

CNC drilling cycle operations Use the CNC drilling cycle as instructed below in order to optimize the tool performance safely. 1. Start the CNC cycle operation a 2. Move the oil pressure head and securely seal onto the face of the workpiece. a Make sure to position the drill so that the guide pads remain inside the guide bushing when the pressure head is moved towards the workpiece face. 3. Move the BTA drill toward the workpiece b Keep the drill 3 - 5 mm* off the face of the workpiece. * If the machine allows this drill setting in Step 1, move b 3 - 5 mm on to Step 4. 4-1 4. Start the cutting 4-2 4-1 Activate the coolant supply. 4-2 Start the rotation (of the drill, the workpiece, or the drill+workpiece). 4-3 Start the drill feed. 4-2 4-3 5-3 5. Stop the cutting 5-1 Stop the drill feed. 5-2 5-2 5-2 Stop the rotation. 5-1 5-3 Stop the coolant supply. c Stop the cutting when the drill shoulder c is completely through the end face of theworkpiece. 6. Return the drill to the starting point 7. Return the oil pressure head to the starting point 24 www.tungaloy.com

Каталог Tungaloy инструмент для автоматов швейцарского типа

Каталог Tungaloy инструмент для автоматов швейцарского типа Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1