Каталог Tungaloy глубокое сверление 1 - страница 20

Навигация

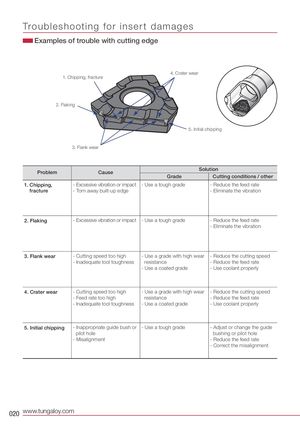

Tr o u b l e s h o o t i n g for insert damages Examples of trouble with cutting edge 4. Crater wear 1. Chipping, fracture 2. Flaking 5. Initial chipping 3. Flank wear Problem Cause Solution Grade Cutting conditions / other 1. Chipping, - Excessive vibration or impact - Use a tough grade - Reduce the feed rate fracture - Torn away built-up edge - Eliminate the vibration 2. Flaking - Excessive vibration or impact - Use a tough grade - Reduce the feed rate - Eliminate the vibration 3. Flank wear - Cutting speed too high - Use a grade with high wear - Reduce the cutting speed - Inadequate tool toughness resistance - Reduce the feed rate - Use a coated grade - Use coolant properly 4. Crater wear - Cutting speed too high - Use a grade with high wear - Reduce the cutting speed - Feed rate too high resistance - Reduce the feed rate - Inadequate tool toughness - Use a coated grade - Use coolant properly 5. Initial chipping - Inappropriate guide bush or - Use a tough grade - Adjust or change the guide pilot hole bushing or pilot hole - Misalignment - Reduce the feed rate - Correct the misalignment 020 www.tungaloy.com

Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy инструмент для автоматов швейцарского типа

Каталог Tungaloy инструмент для автоматов швейцарского типа Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование