Каталог Tungaloy глубокое сверление 1 - страница 18

Навигация

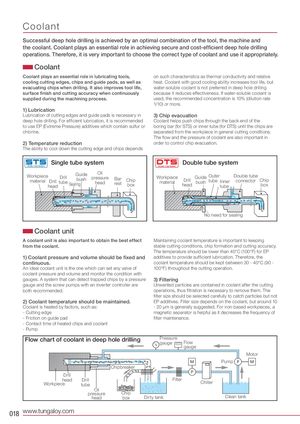

Coolant Successful deep hole drilling is achieved by an optimal combination of the tool, the machine and the coolant. Coolant plays an essential role in achieving secure and cost-efficient deep hole drilling operations. Therefore, it is very important to choose the correct type of coolant and use it appropriately. Coolant Coolant plays an essential role in lubricating tools, on such characteristics as thermal conductivity and relative cooling cutting edges, chips and guide pads, as well as heat. Coolant with good cooling ability increases tool life, but evacuating chips when drilling. It also improves tool life, water-soluble coolant is not preferred in deep hole drilling surface finish and cutting accuracy when continuously because it reduces effectiveness. If water-soluble coolant is supplied during the machining process. used, the recommended concentration is 10% (dilution rate 1/10) or more. 1) Lubrication Lubrication of cutting edges and guide pads is necessary in 3) Chip evacuation deep hole drilling. For efficient lubrication, it is recommended Coolant helps push chips through the back end of the to use EP (Extreme Pressure) additives which contain sulfur or boring bar (for STS) or inner tube (for DTS) until the chips are chlorine. separated from the workpiece in general cutting conditions. The flow and the pressure of coolant are also important in 2) Temperature reduction order to control chip evacuation. The ability to cool down the cutting edge and chips depends Single tube system Double tube system Workpiece material Drill head Drill tube Guide bush Sealing OilpressureheadBarChiprestboxWorkpiecematerialDrillheadGuidebushOutertubeInnertubeDouble tubeconnectorChipbox No need for sealing Coolant unit A coolant unit is also important to obtain the best effect Maintaining coolant temperature is important to keeping from the coolant. stable cutting conditions, chip formation and cutting accuracy. The temperature should be lower than 40°C (100°F) for EP 1) Coolant pressure and volume should be fixed and additives to provide sufficient lubrication. Therefore, the continuous. coolant temperature should be kept between 30 - 40°C (90 - An ideal coolant unit is the one which can set any valve of 100°F) throughout the cutting operation. coolant pressure and volume and monitor the condition with gauges. A system that can detect trapped chips by a pressure 3) Filtering gauge and the screw pumps with an inverter controller are Unwanted particles are contained in coolant after the cutting both recommended. operations, thus filtration is necessary to remove them. The filter size should be selected carefully to catch particles but not 2) Coolant temperature should be maintained. EP additives. Filter size depends on the coolant, but around 10 Coolant is heated by factors, such as: - 20 μm is generally suggested. For iron-based workpieces, a - Cutting edge magnetic separator is helpful as it decreases the frequency of - Friction on guide pad filter maintenance. - Contact time of heated chips and coolant - Pump Flow chart of coolant in deep hole drilling Pressuregauge Flow gauge Motor M Pump P M Chipbreaker P Drill head DrillWorkpiecetube Filter Chiller Oil pressure ChipheadboxDirty tank Clean tank 018 www.tungaloy.com

Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy инструмент для автоматов швейцарского типа

Каталог Tungaloy инструмент для автоматов швейцарского типа Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование