Каталог TooTool техническая информация 2 - страница 5

Навигация

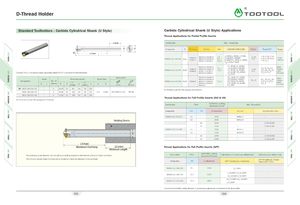

D-Thread Holder .A\V/ Standard Toolholders - Carbide Cylindrical Shank (U Style) Carbide Cylindrical Shank (U Style) Applications Thread Applications for Partial Profile Inserts rL3 (min)— Tool holder Min. Thread Dia. t dL2.7LI (max), Designation D ISO Coarse ISO Fine UNC UN/UNF/UNEF/UNS BSP(G) Partial 55° Trapez L SR0021-11U-E16-135 20.65 M24X3.0M30X3.5M22X0.5; M22x0.75M22x1.0; M23xl.25M23x1.5; M23x2.0.1-8, 1V -7Is/ -67/S-32UN;7/S-28UN;7/8-27UNS;7/S-24UNS;7/8-20UNEF;1-18UNS;15/16-16UN;1-14UNS;15/16-12UN;1-10UNS 3/4-141- 11 1-26; 1-20; 1-16;1-12; 1-10; lV8-91-8; lV8-7(TR 26-TR60)x3 Coolant-Thru is recommended, especially when D>0.7 x nominal thread diameter M27X0.5; M27x0.75SR0026-11U-E20-17526.00M30X3.5M36x4.0M28X1.0; M28X1.25M28x1.5; M29X2.01lVs/84--76M30x2.5; M30x3.01VS- 28UN; ll/8-24UNS;1V8-20UN;1V8-18UNEF;- iy8-16UN; iy8-14UNS;iy 12UNF; 13/ -10UNS;17/-8UN,7/ -141- 11lV,-26; lV,-20;13/,6-16; 1J/16-12;* 13/I6-8;l/4-7(TR40-TR60)x3(TR65 -TR110)x4 16 Spare partsStockDimensions(mm)Insert SizeDesignationNo. ofRLInsertsDdLI(max)L2L3(min)LLd&screwWrench M32X0.5; M32x0.75M33X1.0; M33X1.25SR0031-11U-E25-19031.00M36x4.0M33X1.5; M34X2.0lV2-6M34x2.5; M35X3.0M36X3.515/16-28UN; iy2-24UNS;iy2-20UN;iy2-18UNEF;l3/8-16UN;l3/s-14UNS;l3/8-12UNF;l3/8-10UNS;17/-8UN 16 l1/,-11 ,l3/16-26; lV16-20;l3/ -16; 13/S-12;l7/16-8(TR50-TR60)x3(TR65-TR110)x4 SR 0021-11U - E16-135 2 20.65 * 16 80 5.4 34 135 For TR inserts use the CNC program (D+0.25mm). 0026-11U-E20-175 3 26.00 20 120 5.4 40 175 111) 6.35U Y 55 - SSTX 2.5 -3.6P TPF-08 0031-11U- E25 -190 4 31.00 25 140 5.4 46 190 Thread Applications for Full Profile Inserts (ISO & UN) For TR inserts use the CNC program (D+0.25mm). Tool holder Pitch Toolholder cuttingdiameter D (mm) Min. Thread Dia Designation mm TPI D Adjustment ISO Fine UN/UNF/UNEF/UNS SR0026-11U-E20-175 1.5 25.00 M28X1.5 Holding Device 2.0 24.85 M29X2.0 wmmm 14 24.94 11/8-14UNS1224.8511/8-12UNF t SR0031-11U- E25 -190 1.5 30.00 M33X1.5 D 2.0 29.85 M34x2.0 mmmmmA 14 29.94 13/8-14UNS1229.851 3/8-12UNF L1 (max ) Maximum Overhang L3 (min) Thread Applications for Full Profile Inserts (NPT) Minimum Length The overhang-to-bar diameter ratio should be as small as possible to eliminate the chance of chatter (vibration). Tool holder Pitch Toolholder cuttingdiameter D2 (mm)Cylindrical or Conical pre-drilled hole Cylindrical pre-drilled hole The minimum length inside a holding device should be 2 times the diameter of the bar shank. NPT Threading by 2 Radial Designation TPI D Adjustment NPT Threading by 1Radial Pass Passes (50% / 50%) SR0021-11U- E16-135 14 20.49 3/4-14NPT SR0026-11U-E20-175 11.5 25.63 1-11.5NPT; 174-11.5NPT; 172-11.5NPT; 2-11.5NPT SR0031-11U-E25 -190 11.5 30.63 174-11.5NPT; 172-11.5NPT; 2-11.5NPT Correct the toolholder cutting diameter D according to adjustment, as indicated in the above table. 365 366

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы