Каталог TooTool техническая информация 2 - страница 49

Навигация

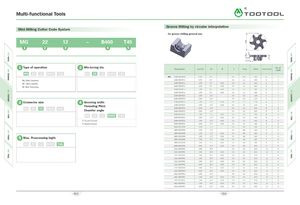

Multi-functional Tools A\ Groove Milling by circular interpolation Mini Milling Cutter Code System for groove milling general use 22 12 B400 T45 t max. Type of operation Min.boring dia Designation b ±0.02 Ds R S tmax Dmin Connector No ofTeeth MG mm MG 1006-B050T08 0.50 9.7 3.5 0.8 10.0 6 3 MG: Mini Grooving 1006-B070T11 0.70 9.7 3.5 1.1 10.0 6 3 MC: Mini Chamfer 1006-B100T15 1.00 9.7 0.10 3.5 1.5 10.0 6 3 MI: Mini Threading 1006-B150T15 1.50 9.7 0.20 3.5 1.5 10.0 6 3 1006-B200T15 2.00 9.7 0.20 3.5 1.5 10.0 6 3 1006-B250T15 2.50 9.7 0.20 3.5 1.5 10.0 6 3 1206-B100T25 1.00 11.7 3.5 2.5 12.0 6 3 1206-B150T25 1.50 11.7 3.5 2.5 12.0 6 3 Connector size Grooving width 1206-B200T25 2.00 11.7 0.20 3.5 2.5 12.0 6 3 Threading Pitch 1206-B250T25 2.50 11.7 0.20 3.5 2.5 12.0 6 3 MG Chamfer angle 1608-B100T35 1.00 15.7 5.5 3.5 16.0 8 61608-B150T351.5015.75.53.516.086 I‘ B400 T45 1608-B200T35 2.00 15.7 0.20 5.5 3.5 16.0 8 61608-B250T352.5015.70.205.53.516.086 B: Square Groove 1608-B300T35 3.00 15.7 0.20 5.5 3.5 16.0 8 6 R: Round Groove 1608-B400T35 4.00 15.7 0.20 5.5 3.5 16.0 8 6 1809-B120T40 1.20 17.7 5.5 4.0 18.0 9 6 1809-B150T40 1.50 17.7 5.5 4.0 18.0 9 6 1809-B200T40 2.00 17.7 0.20 5.5 4.0 18.0 9 6 Max. Proecessing legth 1809-B250T40 2.50 17.7 0.20 5.5 4.0 18.0 9 6 1809-B300T40 3.00 17.7 0.20 5.5 4.0 18.0 9 6 B400I T45 1809-B350T40 3.50 17.7 0.20 5.5 4.0 18.0 9 6 1809-B400T40 4.00 17.7 0.20 5.5 4.0 18.0 9 6 2212-B150T45 1.50 21.7 5.9 4.5 22.0 12 6 2212-B200T45 2.00 21.7 0.20 5.9 4.5 22.0 12 6 2212-B250T45 2.50 21.7 0.20 5.9 4.5 22.0 12 6 2212-B300T45 3.00 21.7 0.20 5.9 4.5 22.0 12 6 2212-B350T45 3.50 21.7 0.20 5.9 4.5 22.0 12 6 2212-B400T45 4.00 21.7 0.20 5.9 4.5 22.0 12 6 2212 - B500T45 * 5.00 21.7 0.20 5.2 4.5 22.0 12 6 2212-B600T45* 6.00 21.7 0.20 5.2 4.5 22.0 12 6 2412-B150T55 1.50 23.7 5.9 5.5 24.0 12 6 2412-B200T55 2.00 23.7 0.20 5.9 5.5 24.0 12 6 2412-B250T55 2.50 23.7 0.20 5.9 5.5 24.0 12 6 2412-B300T55 3.00 23.7 0.20 5.9 5.5 24.0 12 6 2412-B400T55 4.00 23.7 0.20 5.9 5.5 24.0 12 6 453 454

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы