Technical Information for SMT Carbide Avy\

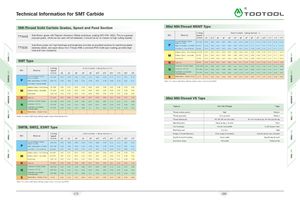

Mill-Thread Solid Carbide Grades, Speed and Feed Section Mini Mill-Thread MSMT Type

Cutiing Feed mm/tooth Cutting Diameter=D

TTIM45 Sub-Micron grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20). This is a generalpurpose grade, which can be used with all materials; it should be run at medium to high cutting speeds.ISOMaterial Speedm/min q>1 2 12% Si 60-140 0.03 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.10 0.11 0.13 0.14

m/min tp2 cp3 cp4 10 0.55%C 100-145 0.02 0.03 0.03 0.05 0.06 0.07 0.08 0.09 0.10 0.12 0.15 Note: For cutters with long cutting length reduce feed rate by 40%V

Alloy Steels, Treated Steels

Stainless Steels - Free Cutting 55 -130 0.02 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.11

M Stainless Steels - Austenitic 55 -100 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

Cast Steels 120-135 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

K Cast Iron 65 -120 0.03 0.04 0.04 0.06 0.07 0.08 0.09 0.11 0.12 0.15 0.18 Mini Mill-Thread VS Taps

Aluminum 512%Si, Copper 135 - 280 0.03 0.04 0.04 0.06 0.07 0.08 0.09 0.11 0.12 0.15 0.18

N Aluminum >12% Si 90-200 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

Synthetics, Duroplastics,Thermoplastics90- 320 0.05 0.06 0.07 0.08 0.1 0.11 0.12 0.14 0.15 0.18 0.22 Feature Mini Mill-Thread Taps

S Nickel Alloys, Titanium Alloys Thread surface quality High Medium

Note: For cutters with long cutting length reduce feed rate by 40% Thread geometry Very accurate Medium

Thread tolerances 4H, 5H, 6H with std cutter 6H with standard tap, 4H with specific tap

Machining time Same as tap or shorter Short

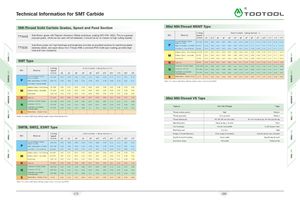

SMTB, SMTZ, ESMT Type Tool breakage Almost not possible Could happen often

Machining load Very low High

Cutiing Feed mm/tooth Cutting Diameter=D Range of thread diameters Wide range of diameters Specific tap for each diameter

ISO Material Speedm/min cp2 q>3 cp4 96 98 9IO 912 914 916 920 925 Right/Left hand threading Same cutter Specific tap for each

Low and Medium Carbon 100-250 0.03 0.04 0.04 0.06 0.07 0.08 0.09 0.11 0.12 0.15 0.18 Geometric shape Full profile Partial profile

Steels <0.55%C

P High Carbon Steels >0.55%C 110-180 0.02 0.03 0.03 0.05 0.06 0.07 0.08 0.09 0.10 0.12 0.15

Alloy Steels, Treated Steels 90-160 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

Stainless Steels - Free Cutting 60-160 0.02 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.11

M Stainless Steels - Austenitic 60-120 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

Cast Steels 130-170 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

K Cast Iron 70-150 0.03 0.04 0.04 0.06 0.07 0.08 0.09 0.11 0.12 0.15 0.18

Aluminum <12%Si, Copper 150-350 0.03 0.04 0.04 0.06 0.07 0.08 0.09 0.11 0.12 0.15 0.18

N Aluminum >12% Si 100-250 0.02 0.02 0.03 0.03 0.04 0.05 0.05 0.06 0.07 0.08 0.10

Synthetics, Duroplastics, 100-400 0.05 0.06 0.07 0.08 0.1 0.11 0.12 0.14 0.15 0.18 0.22

Thermoplastics

S Nickel Alloys, Titanium Alloys 20-80 0.02 0.02 0.02 0.03 0.03 0.03 0.03 0.04 0.04 0.04 0.05

Note: For cutters with long cutting length reduce feed rate by 40%V

379 380

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы