Каталог TooTool техническая информация 2 - страница 10

Навигация

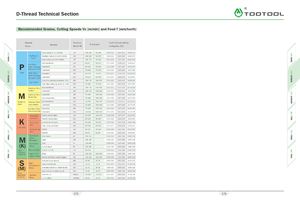

D-Thread Technical Section A\ 4' Recommended Grades, Cutting Speeds Vc [m/min] and Feed f [mm/tooth] Material Hardness Feed* f [mm/tooth] by Group Material Vc [m/min]Brinell HB Cutting Dia. (D2) Low Carbon (C=0.1-0.25%) 125 100-210 90-180 0.20-0.32 0.30-0.50 0.30-0.75 Unalloyed Medium Carbon (C=0.25-0.55%) 150 100-180 90-170 0.20-0.32 0.30-0.50 0.30-0.75 Steel High Carbon (C=0.55-0.85%) 170 100-170 90-160 0.15 -0.23 0.25 -0.35 0.25 -0.52 Low Alloy Non Hardened 180 60-90 90-155 0.17-0.28 0.28-0.45 0.28-0.67 Steel (alloying Hardened 275 80-150 80-160 0.15-0.28 0.25 -0.45 0.25 -0.67 elements < 5%) Hardened 350 70-140 70-150 0.15 -0.25 0.25-0.40 0.25-0.60 Steel High Alloy Annealed 200 60-130 70-115 0.15-0.22 0.20-0.30 0.20-0.45 Steel (alloying elements> 5%) Hardened 325 70-110 60-100 0.13-0.21 0.18-0.30 0.18-0.45 Low Alloy (alloying elements < 5%) 200 100-170 100-170 0.15-0.22 0.20-0.30 0.20-0.45 Cast Steel High Alloy (alloying elements >5%) 225 70-120 70-130 0.12-0.22 0.17-0.30 0.17-0.45 Stainless Steel Non Hardened 200 100-170 120-180 0.15 -0.22 0.22-0.34 0.22-0.50 Ferritic Hardened 330 100-170 120-180 0.16-0.23 0.21-0.32 0.21-0.48 Stainless Steel Austenitic 180 70-140 100-140 0.15 -0.25 0.25 -0.40 0.25 -0.60 Austenitic Super Austenitic 200 70-140 100-140 0.12-0.20 0.17-0.26 0.17-0.39 Stainless Stainless Steel Non Hardened 200 70-140 100-140 0.16-0.24 0.25-0.37 0.25-0.55 steel Cast Ferritic Hardened 330 70-140 100-140 0.12-0.20 0.17-0.26 0.17-0.39 Stainless Steel Austenitic 200 70-120 100 - 120 0.15-0.22 0.20-0.30 0.20-0.45 zLUZ3 Cast Austenitic Hardened 330 70-120 100-120 0.12-0.20 0.17-0.26 0.17-0.39 d Malleable Ferritic (short chips) 130 60-130 100 - 120 0.16-0.24 0.25 -0.37 0.25 -0.55 2 K Cast Iron Pearlitic (long chips)Grey CastLow Tensile Strength230 60-120 80-100 0.15 -0.22 0.20-0.30 0.20-0.4518060-13080-1000.15 -0.220.22-0.340.22-0.50 Iron High Tensile Strength 260 60-100 80-100 0.15 -0.22 0.20-0.30 0.20-0.45 Cast iron Nodular Sg Ferritic 160 60-125 80-100 0.10-0.20 0.15 -0.25 0.15 -0.37 Iron Pearlitic 260 50-90 60-90 0.15-0.22 0.20-0.30 0.20-0.45 Aluminum Non Aging 60 100-250 0.30-0.50 0.60-1.00 0.60-1.50 M AlloysWrought Aged 100 100-180 0.28-0.50 0.50-0.90 0.50-1.20 (K) AluminumAlloys CastCast & Aged 75 150-400 0.28-0.50 0.50-0.90 0.50-1.2090150-2800.25 -0.400.40-0.600.40-0.90 Non- Aluminum Alloys Cast Si 13-22% 130 80-150 0.28-0.50 0.50-0.90 0.50-1.20 Ferrous material opper and Brass 90 120-210 100-200 0.30-0.50 0.60-1.00 0.60-1.50 Copper Alloys Bronze and Non Leaded Copper 100 120-210 100-200 0.28-0.50 0.50-0.90 0.50-1.20 S Annealed (iron based)HighAged (iron based)Temperature200 20-45 20-40 0.09-0.15 0.12-0.22 0.12-0.3328020-3020-300.07-0.130.10-0.200.10-0.30 (M) Alloys Annealed (nickel or cobalt based) 250 15-20 15-20 0.08-0.15 0.08-0.20 0.08-0.30 Aged (nickel or cobalt based) 350 10-15 10-15 0.08-0.15 0.08-0.20 0.08-0.30 Heat Resistant Titanium Pure 99.5 Ti 400Rm 70-140 70-120 0.07-0.13 0.10-0.20 0.10-0.30 material Alloys a +3 alloys 1050Rm 20- 50 20- 50 0.07-0.13 0.10-0.20 0.10-0.30 375 376

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы