Каталог TooTool техническая информация 1 - страница 78

Навигация

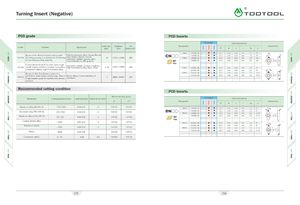

Turning Insert (Negative) A\ PCD grade PCD Inserts Uncoated Dimensions(mm) Grade Features Application Grain size Hardness TRS(pm)(Hv)(kgf/mm2) Designation I IC d s r la a Geometries CNGA 120404-IN 12.7 5.16 4.76 0.4 2.5 0° TDP10E By use of the diamond grain having goodbonding property, it is suitable for machiningof non-ferrous metal, graphite.High Si aluminum alloy, Copper, Bronzealloy, Rubber, Wood, Carbon,Cemented carbide, ceramic semi-sintered products, FRP, graphite1010000-12000200CNOO120408-IN12.75.164.760.82.50°CNGX120404-IN12.75.164.760.42.510°80°120408-IN12.75.164.760.82.510° TDP30E Coarse diamond grain has been used to getexcellent wear resistance enough to machineCemented . carbide Ceramic roughing,High Si aluminum alloy, Rock, stone2-3010000-12000110Nega CNGA 120404-2N 12.7 5.16 4.76 0.4 2.5 0° cemented-carbide, high Si aluminum alloy. 120408-2N 12.7 5.16 4.76 0.8 2.5 0° By use of ultra fine diamond grain, it is CNGX 120404-2N 12.7 5.16 4.76 0.4 2.5 3°- 5° TDP01E possible to make sharp cutting edge,. Thus itis appropriate grade to machine non-ferrousPlastic, Wood, Precise finishing ofaluminum1- 800010000220 120408-2N 12.7 5.16 4.76 0.8 2.5 3°-5° material Recommended cutting condition PCD Inserts Recommended gradeWorkpieceCutting speed (m/min)Feed (mm/rev)Depth of cut (mm) Uncoated Dimensions(mm) 1st 2nd Designation Geometries f e IC d s r la a Aluminum alloy (4%-8% Si) 1000-3000 0.10-0.60 ~3 TDP10E TDP30E DNGA 150404-IN 12.7 5.16 4.76 0.4 2.5 0° Aluminum alloy (9%-14% Si) 600-2500 0.10-0.50 -3 TDP10E TDP30E DNOO 150408-IN 12.7 5.16 4.76 0.8 2.5 0°DNGX150404-IN12.75.164.760.42.53°-5° Aluminum alloy (15%-18% Si) 300-700 0.10-0.40 -3 TDP10E TDP30E /57 55° Nega 150408-IN 12.7 5.16 4.76 0.8 2.5 3°-5° Cooper, Bronze alloy -1000 0.05-0.20 -3 TDP10E TDP01E DNGA 150404-2N 12.7 5.16 4.76 0.4 2.5 0” Reinforced plastic -1000 0.10-0.30 -2 TDP10E TDP01E 150408-2NDNGX150404-2N 12.7 5.16 4.76 0.8 2.5 .0”12.75.164.760.42.53 -50 Wood -4000 0.10-0.40 TDP10E TDP01E 150408-2N 12.7 5.16 4.76 0.8 2.5 3°-5° Cemented carbide 10-30 -0.20 -0.5 TDP30E TDP10E 155 156

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2