Каталог TooTool техническая информация 1 - страница 69

Навигация

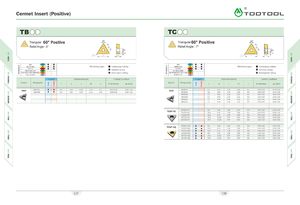

Cermet Insert (Positive) A\ 111 TBOO TCOO Triangular 60° PositiveORelief Angle : 5° Trianguiar 60° PositiveORelief Angle : 7° Idlt R 5' t RrfTdi Steel P Steel P CDu Stainless steelQ.Cast ironMK Sm *o§Non-ferrous metalNHeat resistant alloy,Titaium Hardened steel ^ alloy SHMachining types0 Continuous cuttingS General cuttingInterrupted cutting uCD Stainless steelCLCast ironMK * S9goNon-ferrous metalNHeat resistant alloy,Titaium Hardened steel ^ alloy SHMachining types#Continuous cutting$ General cuttingInterrupted cutting Coated Dimensions(mm) Cutting Condition Coated Dimensions(mm) Cutting Condition Inserts Designation ym m I d t dl r fn (mm/rev) ap (mm) Inserts Designation R 21 yinm I£ d t dl r fn (mm/rev) ap (mm) TBGT 060102L 6.4 3.97 1.59 2.16 0.2 0.05-0.20 0.10-1.30 TCGT 060102L 6.4 3.97 1.59 2.16 0.2 0.05 -0.20 0.10-1.30 060104L 5.8 3.97 1.59 2.16 0.4 0.08-0.20 0.10-1.30 060104L 5.8 3.97 1.59 2.16 0.4 0.08-0.20 0.10-1.30 080202R 7.7 4.76 2.38 2.30 0.2 0.03-0.11 0.06-1.70 080204R 7.2 4.76 2.38 2.30 0.4 0.05-0.15 0.06-2.00 080202L 7.7 4.76 2.38 2.30 0.2 0.03-0.11 0.06-1.70 080204L 7.2 4.76 2.38 2.30 0.4 0.05-0.15 0.06-2.00 TCMT- PS 090204-PS 8.6 5.56 2.38 2.50 0.4 0.05 -0.20 0.10-1.70 110202-PS 10.5 6.35 2.38 2.80 0.2 0.03-0.13 0.06-1.70 110204-PS 10.0 6.35 2.38 2.80 0.8 0.05 -0.20 0.30-1.20 16T304-PS 15.5 9.525 3.97 4.40 0.4 0.05-0.20 0.30-1.50 16T308-PS 14.5 9.525 3.97 4.40 0.8 0.10-0.25 0.30-1.50 TCMT- HQ 090204-HQ110202 - HQ 8.6 5.56 2.38 2.50 0.4 0.08-0.16 0.50-2.0010.56.352.382.800.20.07-0.140.50-2.00 110204- HQ 10.0 6.35 2.38 2.80 0.8 0.08-0.16 0.50-2.00 110208-HQ 9.0 6.35 2.38 2.80 0.8 0.10-0.20 0.50-2.00 16T304-HQ 15.5 9.525 3.97 4.40 0.4 0.08-0.20 0.50-2.00 16T308-HQ 14.5 9.525 3.97 4.40 0.8 0.10-0.25 0.50-2.00 137 138

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2