Каталог TooTool техническая информация 1 - страница 63

Навигация

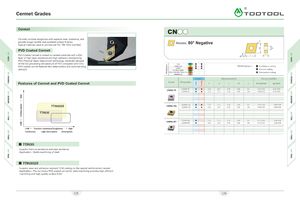

Cermet Grades A\

Cermet CNOO

Cermets combine toughness with superior wear resistance, andprovide longer toollife and excellent surface finishes.Typical materials used in cermets are TiC, TiN, TiCN and NbC.[o ] Rhombic 80° Negative r

PVD Coated Cermet O d -3*

PVD Coated Cermet is coated on cermet substrate with a thin v80 i t

layer of high wear resistance and high adhesion resistance by

PVD (Physical Vapor Deposition) technology. Generally because

of the low processing temperature of PVD compared with CVD, Steel

PVD coated cermet features less deterioration and more bendingstrength. fI Stainless steelCast ironNon-ferrous metalHeat resistant alloy, Titaium alloy

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2