Каталог TooTool техническая информация 1 - страница 30

Навигация

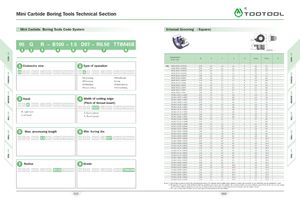

Mini Carbide Boring Tools Technical Section A\ Mini Carbide Boring Tools Code System Internal Grooving ( Square) D - B100 - 1.5 D07 - R0.50 TTIM45B Designation(Internal) b S f a d tmax Dmin R OConnector size Type of operation MB 04GR-B050-1.0D055 0.50 2.6 3.2 5.2 4 1.0 5.504GR-B070-1.0D0550.702.63.25.241.05.5 -a D07 04GR-B100-1.0D055 1.00 2.6 3.2 5.2 4 1.0 5.504GR-B150-1.0D0551.502.63.25.241.05.5 04GR-B200-1.0D055 2.00 2.6 3.2 5.2 4 1.0 5.5 GR:grooving PR:Profiling& 04GR-B100-1.4D06 1.00 2.6 3.7 5.7 4 1.4 6.0 QR:Copying boring 04GR-B120-1.4D06 1.20 2.6 3.7 5.7 4 1.4 6.0 04GR-B150-1.4D06 1.50 2.6 3.7 5.7 4 1.4 6.0 IR:Threading XR:Back boring 04GR-B200-1.4D06 2.00 2.6 3.7 5.7 4 1.4 6.0 FR:Face cutting CR:Chamfering 04GR-B100-2.3D07 1.00 2.6 4.7 6.7 4 2.3 6.0 04GR-B150-2.3D07 1.50 2.6 4.7 6.7 4 2.3 6.0 04GR-B200-2.3D07 2.00 2.6 4.7 6.7 4 2.3 6.0 05GR/L-B050-1.4D07 0.50 3.3 4.3 6.8 4 1.4 7.0 Hand Width of cutting edge 05GR/L-B075-1.4D07 0.75 3.3 4.3 6.8 5 1.4 7.005GR/L-B080-1.4D070.833.34.36.851.47.0 EEa (Pitch of thread insert) 05GR/L-B090-1.4D07 0.93 3.3 4.3 6.8 5 1.4 7.005GR/L-B100-1.4D071.003.34.36.851.47.0 B100 05GR/L-B120-1.4D07 1.20 3.3 4.3 6.8 5 1.4 7.0 05GR/L-B140-1.4D07 1.40 3.3 4.3 6.8 5 1.4 7.0 R: right hand B: Square groove 05GR/L-B150-1.4D07 1.50 3.3 4.3 6.8 4 1.4 7.0 L: left hand R: Round groove 05GR/L-B170-1.4D07 1.60 3.3 4.3 6.8 5 1.4 7.005GR/L-B200-1.4D072.003.34.36.851.47.0 05GR/L-B100-2.3D08 1.00 3.3 5.2 7.7 5 2.3 8.0 05GR/L-B150-2.3D08 1.50 3.3 5.2 7.7 5 2.3 8.0 05GR/L-B200-2.3D08 2.00 3.3 5.2 7.7 5 2.3 8.0 05GR/L-B100-2.8D09 1.00 3.3 5.8 8.3 5 2.8 9.0 05GR/L-B150-2.8D09 1.50 3.3 5.8 8.3 5 2.8 9.0 Max. processing length Min. boring dia 05GR/L-B200-2.8D09 2.00 3.3 5.8 8.3 5 2.8 9.0 05GR/L-B250-2.8D09 2.50 3.3 5.8 8.3 5 2.8 9.0 ri - ETPli]- -S D07 05GR/L-B300-2.8D09 3.00 3.3 5.8 8.3 5 2.8 9.007GR/L-B075-2.0D100.733.56.09.572.010.0 07GR/L-B080-2.0D10 0.83 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B090-2.0D10 0.93 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B100-2.0D10 1.00 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B120-2.0D10 1.20 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B140-2.0D10 1.40 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B150-2.0D10 1.50 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B170-2.0D10 1.70 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B200-2.0D10 2.00 3.5 6.0 9.5 7 2.0 10.0 07GR/L-B250-2.0D10 2.50 3.5 6.0 9.5 7 2.0 10.0 Radius Grade 07GR/L-B300-2.0D10 3.00 3.5 6.0 9.5 7 2.0 10.007GR/L- B100- 3.0D111.003.57.010.573.011.0 07GR/L- B150- 3.0D11 1.50 3.5 7.0 10.5 7 3.0 11.0 -Enao-EBES R0.50 TTIM45B 07GR/L- B200- 3.0D11 2.00 3.5 7.0 10.5 7 3.0 11.0 07GR/ L - B250- 3.0D11 2.50 3.5 7.0 10.5 7 3.0 11.0 07GR/L- B300- 3.0D11 3.00 3.5 7.0 10.5 7 3.0 11.0 07GR/ L - B100 - 3.5D12 1.00 3.5 7.5 11.0 7 3.5 12.0 07GR/L- B150- 3.5D12 1.50 3.5 7.5 11.0 7 3.5 12.0 Note: 1. 05GR type insert is not in the standard inventory, for deeper and smaller sizes, please contact the supplier to ask whether can be grinded or not? 2. 09 type insert can be drilled 16mm hole by grinding the insert and the holder, the cutting depth can reach 6.0mm, and 17mm hole can cut the depth up to 7.0mm. When using the insert, try to choose the holder with a short and thick overhang and the wider insert 3. You can contact the supplier if you have special requirements for the radius. 059 060

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2