Каталог TooTool техническая информация 1 - страница 2

Навигация

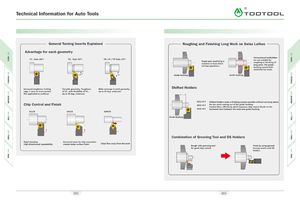

Technical Information for Auto Tools A\ General Turning Inserts Explained Roughing and Finishing Long Work on Swiss Lathes Advantage for each geometryCC.. Style (80°)DC.. Style (55°) VB / VC / VP Style (35°)§•I ' -30'45- I Conventional toolholdersSingle pass machining is. common in Swiss frontturning operations-Dare not suitable for. roughing or finishing oflong partsThe guide-. bushing cannot holdmachined bar stockGuide-bushingGuide-bushing . Increased toughness Cutting. edge is close to insert pocketNot applicable to undercut. Versatile geometryToughness.. .. of CCwith flexibility of VC. Up to 30 degundercutsWide Up to . coverage in work geometry . 45 deg undercutsShifted Holders1 Chip Control and FinishSCLCR SDJCR SDNCN :u@ SCLC -N- FSDJC -N - FShifted the bar . Holders make a finishing process possible stock coming out of the guide-bushing without worrying aboutSVJC-N-FCoolant flows effectively increased room between . which improves chip control thanks the tools and guide-bushing to the Guide-bushing Sh Combination of Grooving Tool and DS Holders Rigid clamping Increased room for chip evacuation High dimensional repeatability creates better surface finish Chips flow away from the work Rough with grooving tool Finish by using general for good chip control turning inserts with DS Holders 3 t*t 003 004

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2