Каталог TooTool техническая информация 1 - страница 173

Навигация

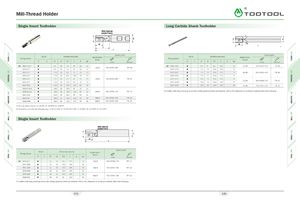

Mill-Thread Holder .A\V/ Single Insert Toolholder Long Carbide Shank Toolholder With internal coolant bore D i I( ny d D [ ^ vwwwvwap ap tDl < ^ L 1 L Spare parts Spare parts StockDesignation Dimensions(mm) ApplicationInsert # StockDesignation Dimensions(mm) ApplicationInsert R L D d D1 L i ap screw Wrench R L D d D1 L 2 ap screw Wrench SR 0009 - H12(1) 9.5 20 7.5 85 14 12 SR 0010-K12C 9.9 8 8.0 125 12 12E/N Y 50- SSTX 3 -4.0P TPF-08 12E/N Y 50- SSTX 3 -4.0P TPF-08 0010 - H12 9.9 20 7.6 85 16 12 0013-H14C 13.2 10 10.0 110 14 0012-F14 12.0 20 8.9 75 20 14 0013-J14C 13.2 10 10.0 155 14 14E/N Y 50- SSTX 3 -4.0P TPF-08 0012-H14 12.0 20 8.9 100 30 14 0015 - K14C 15.2 12 12.0 175 14 0014 - H14 14.5 20 11.2 85 25 14 14E/N Y 50- SSTX 3 -4.0P TPF-10 0021-K21C 21.0 16 16.0 130 21 21E/N Y60- SSTX4- 5.7P TPF-15 0017 - H14 17.0 20 13.4 85 30 14 0021- M21C 21.0 16 16.0 200 21 0017-K14 17.0 20 13.4 120 40 14 0027-S30C 27.0 20 20.0 250 30 30E/N Y50-STX 5 -7.0P TPF-20 0018- 1-121(2) 18.0 20 14.4 85 30 21 0018 - K21(2) 18.0 20 14.4 120 45 21 21E/N Y60- SSTX4- 5.7P TPF-15 For holders with long overhang reduce the cutting speed and feed rate between 20% to 40% (depends on workpiece material, pitch and overhang) 0021- H21 21.0 20 16.5 94 40 21 0029-J30 29.0 25 23.0 110 50 30 30E/N Y 50-SSTX 5 -7.0P TPF-20 0048-M40 48.0 40 35.0 153 78 40 40E/N Y 50-SSTX 5 -7.0P TPF-20 (1) Not for conical inserts: 12-18 NPT, 12-18 NPTF, 12-19 BSPT (2) Cannot be used with the following inserts: 2113.5 ISO, 2118 UN, 2117 UN, 21-11 BSPT, 21-11.5 NPT, 21-11.5 NPTF Single Insert Toolholder With internal coolant bore D © I1T. d ap L Spare parts StockDesignation Dimensions(mm) ApplicationInsert R L D d D1 L 2 ap screw Wrench SR 0025-K21 25 20 20.7 125 21 21E/N Y60-SSTX4- 5.7P TPF-15 0031- M30 31 25 24.5 150 30 0031-Q30 31 25 24.5 180 30 30E/N Y 50-SSTX5 -7.0P TPF-20 0038 - M30 38 32 31.5 150 30 0038 -Q40 38 32 31.5 180 40 40E/N Y 50-SSTX 5 -7.0P TPF-20 0048-R40 48 40 36 210 40 For holders with long overhang reduce the cutting speed and feed rate between 20% to 40% (depends on workpiece material, pitch and overhang) 345 346

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2