Общий каталог Sumitomo 2019 - 2020 - страница 56

Навигация

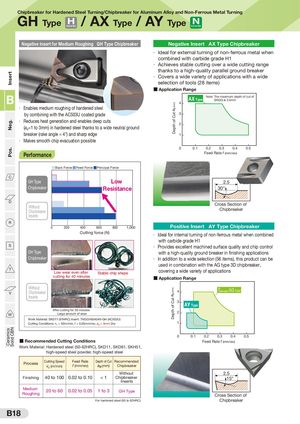

InsertNeg.Pos.CeramicsSolid CBN Depth of Cut ap (mm)Depth of Cut ap (mm) Chipbreaker for Hardened Steel Turning/Chipbreaker for Aluminum Alloy and Non-Ferrous Metal Turning GH Type Hardened Steel / AX Type / AY Type Non-Ferrous Metal Negative Insert for Medium Roughing GH Type Chipbreaker Negative Insert AX Type Chipbreaker · Ideal for external turning of non-ferrous metal when combined with carbide grade H1 · Achieves stable cutting over a wide cutting range thanks to a high-quality parallel ground breaker · Covers a wide variety of applications with a wide selection of tools (28 items) ■ Application Range B AX Type Note: The maximum depth of cut ofSNGG is 3.5mm4 · Enables medium roughing of hardened steel by combining with the AC503U coated grade 3 · Reduces heat generation and enables deep cuts 2 (ap=1 to 3mm) in hardened steel thanks to a wide neutral ground breaker (rake angle = 4°) and sharp edge 1 · Makes smooth chip evacuation possible 0 0.1 0.2 0.3 0.4 0.5 Performance Feed Rate f (mm/rev) Back Force Feed Force Principal Force C GH Type Low 2.5 Chipbreaker Resistance 30° D WithoutChipbreaker Cross Section ofChipbreaker Inserts R 0 200 400 600 800 1,000 Positive Insert AY Type Chipbreaker Cutting force (N) · Ideal for internal turning of non-ferrous metal when combined with carbide grade H1 S · Provides excellent machined surface quality and chip control GH Type with a high-quality ground breaker in nishing applications Chipbreaker · In addition to a wide selection (56 items), this product can be used in combination with the AG type 3D chipbreaker, T Low wear even after Stable chip shape covering a wide variety of applications cutting for 40 minutes ■ Application Range WithoutVChipbreaker 4 3DChipbreaker AG Type Inserts 3 AY Type After cutting for 20 minutes W Large amount of wear 2 Work Material: SKD11 (61HRC) Insert: TNGG160404N-GH (AC503U) Cutting Conditions: vc = 50m/min, f = 0.05mm/rev, ap = 3mm Dry 1 0 0.1 0.2 0.3 0.4 0.5 ■ Recommended Cutting Conditions Feed Rate f (mm/rev) Work Material: Hardened steel (50-62HRC), SKD11, SKD61, SKH51, high-speed steel powder, high-speed steel Process Cutting Speedvc (m/min)Feed Ratef (mm/rev) Depth of Cut Recommendedap (mm)Chipbreaker Without 2.5 Finishing 40 to 100 0.02 to 0.10 <1 Chipbreaker 15° Inserts MediumRoughing 20 to 60 0.02 to 0.05 1 to 3 GH Type Cross Section of For hardened steel (50 to 62HRC) Chipbreaker B18

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019