Общий каталог Sumitomo 2019 - 2020 - страница 21

Навигация

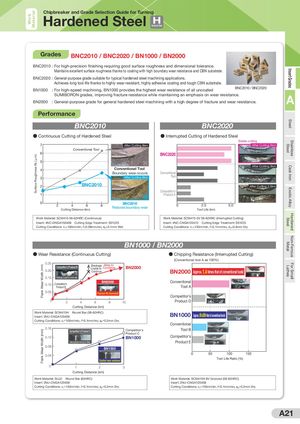

Work MaterialSurface Roughness Rz ( μ m) FlankFlaWnekarWeWiardthW(idmthm) (mm)FlankFlaWnekarWeWiardthWi(dmthm)(mm) For SmallLathesNon-FerrousHardenedMetalSteelExotic AlloyCast IronStainlessSteelSteelInsert Grades Chipbreaker and Grade Selection Guide for Turning Hardened Steel Hardened Steel Grades BNC2010 / BNC2020 / BN1000 / BN2000 BNC2010 : For high-precision finishing requiring good surface roughness and dimensional tolerance. Maintains excellent surface roughness thanks to coating with high boundary wear resistance and CBN substrate. BNC2020 : General-purpose grade suitable for typical hardened steel machining applications. Achieves long tool life thanks to highly wear-resistant, highly adhesive coating and tough CBN substrate. BN1000 : For high-speed machining, BN1000 provides the highest wear resistance of all uncoated BNC2010 / BNC2020 SUMIBORON grades, improving fracture resistance while maintaining an emphasis on wear resistance.BN2000: General-purpose grade for general hardened steel machining with a high degree of fracture and wear resistance. A Performance BNC2010 BNC2020 ● Continuous Cutting of Hardened Steel ● Interrupted Cutting of Hardened Steel Stable cutting 7 After Cutting 8km After Cutting 5km Conventional Tool ■ 6 BNC2020 5 After Cutting 3km 4 ■ Conventional Tool ● Boundary wear occurs Conventional 3 ■ After Cutting 8km Tool 2 ● ●BNC2010 After Cutting 2.5km ●■ Competitor's 1 Product A 0 2 4 6Cutting Distance (km)8 BNC2010Reduces boundary wear 0 2.5 5.0Tool Life (km) Work Material: SCM415 58-62HRC (Continuous) Work Material: SCM415-5V 58-62HRC (Interrupted Cutting) Insert: 4NC-DNGA150408 Cutting Edge Treatment: S01225 Insert: 4NC-CNGA120412 Cutting Edge Treatment: S01225 Cutting Conditions: vc=160m/min, f=0.08mm/rev, ap=0.1mm Wet Cutting Conditions: vc=130m/min, f=0.1mm/rev, ap=0.6mm Dry BN1000 / BN2000 ● Wear Resistance (Continuous Cutting) ● Chipping Resistance (Interrupted Cutting) (Conventional tool A as 100%) 0.25 Competitor's Product B0.250Competitor's Product BBreakage Able toUnable toContinueBN2000BCroenatkinaugeeAble toUnable toContinueBN2000BN2000Approx. 1.4 times that of conventional tools! 0.2105 Breakage caused by crater wear Continue 0.150 CoBrmeapkaegteitcoaur'ssed by crater wear BN2000Product B0.1005Competitor'sProduct BBN2000Fracture life improved!ConventionalTool A 0.050 Fracture life improved!2468 10 Competitor'sProduct D 0 2 Cuttin4g Distanc6e (km) 8 10 Work Material: SCM415H RCouutntidngBaDris(5ta8-n6c2eH(RkmC))Insert: 2NU-CNGA120408 BN1000 Approx. double that of conventional tools! Cutting C0.o1n6ditions: vc=100m/min, f=0.1mm/rev, ap=0.2mm Dry Competitor's Product C Competitor's Conventional 0.160.12 Competitor's Product C Product CCBoNm1pe0t0ito0r's Tool B Product C 0.120.08 Unacceptable Amount of Wear BN1000Unacceptable Amount of WearBN1000 Competitor'sProduct E 0.080.04 BN1000 0.04 Excellent wear resistance! 0 50 100 150 0 1 2Excellent wear resistance! 3 Tool Life Ratio (%) 0 Cu1tting Distance (k2m) 3 Cutting Distance (km) Work Material: SUJ2 Round Bar (62HRC) Work Material: SCM415H 8V Grooved (58-62HRC) Insert: 2NU-CNGA120408 Insert: 2NU-CNGA120408 Cutting Conditions: vc=150m/min, f=0.1mm/rev, ap=0.2mm Dry Cutting Conditions: vc=150m/min, f=0.1mm/rev, ap=0.2mm Dry A21

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019