Общий каталог Sumitomo 2019 - 2020 - страница 115

Навигация

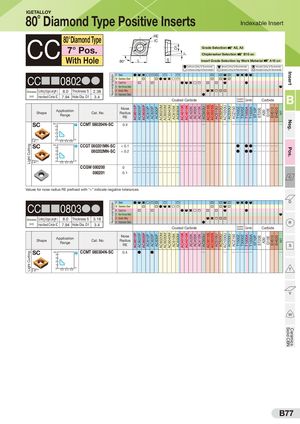

Light CuttingLight Cutting Recommended ApplicationRecommended Application AC8015PAC8015P AC8025PAC8025P AC8035PAC8035P AC810PAC810P AC820PAC820P AC830PAC830P AC6020MAC6020M AC6030MAC6030M AC6040MAC6040M D1AC610MAC630MAC610MAC630M AC4010KAC4010K 7° AC4015KAC4015K AC420KAC420K AC405KAC405K AC415KAC415K AC503UAC503U AC5015SAC5015S AC5025SAC5025S AC510UAC510U AC520UAC520U AC1030UAC1030U AC530UAC530U ACZ150ACZ150 T1500ZT1500Z T3000ZT3000Z T1000AT1000A T1500AT1500A ST10PST10P ST20EST20E A30A30 G10EG10E EH510EH510 EH520EH520 H1H1 CeramicsSolid CBNPos.Neg.Insert IGETALLOY 80˚ Diamond Type Positive Inserts Indexable Insert CC 80°Diamond Type 7° Pos. RE IC Grade Selection A2, A3Chipbreaker SelectionB10 on With Hole 80° L S Insert Grade Selection by Work Material A10 on : Continuous Cutting 1st Recommended : General Cutting 1st Recommended : Interrupted Cutting 1st Recommended : Continuous Cutting 2nd Recommended : General Cutting 2nd Recommended : Interrupted Cutting 2nd Recommended P Steel CC■■0802●● M Stainless SteelKCast Iron N Non-Ferrous Metal Dimensions Cutting Edge Length L 8.0 Thickness S 2.38 S Exotic Alloy (mm) Inscribed Circle IC 7.94 Hole Dia. D1 3.4 H Hardened Steel Coated Carbide CoatedCermet Cermet Carbide B Shape ApplicationRange NoseCat. No.RadiusRE SC (ap)4 CCMT 080204N-SC 0.4 Q Q QQQQQ Q 3 2 1 6° 0 (f )0.20.40.6 SC (ap)4 CCGT 080201MN-SC < 0.1 QQQQQQQQQQQQQQQQQ ● ●●QQQQQQ 3 080202MN-SC < 0.2 QQQQQQQQQQQQQQQQQ ● ●●QQQQQQ 2 1 6° 0 (f )0.20.40.6 CCGW 080200 0 QQQQQQQQQQQ 080201 0.1 QQQQQQQQQQQ C Values for nose radius RE prefixed with "<" indicate negative tolerances. P Steel D CC■■0803●● M Stainless SteelKCast Iron N Non-Ferrous Metal Dimensions Cutting Edge Length L 8.0 Thickness S 3.18 S Exotic Alloy (mm) Inscribed Circle IC 7.94 Hole Dia. D1 3.4 H Hardened Steel RCoated CarbideCoatedCermetCermetCarbide Shape ApplicationRange NoseCat. No.RadiusRE S SC (ap)4 CCMT 080304N-SC 0.4 ● ● Q Q QQQQQ Q 3 2 1 6° 0 (f )0.20.40.6 T V W B77

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019