Общий каталог Sumitomo 2018 - 2019 - страница 570

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

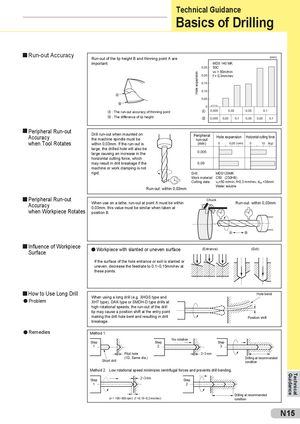

Hole expansion Technical Guidance Basics of Drilling Run-out Accuracy Run-out of the lip height B and thinning point A are (mm) important. MDS 140 MK 0,25 50C vc = 50m/min 0,20 f = 0,3mm/rev 0,15 0,10 0,05 0 A : The run-out accuracy of thinning point A 0,005 0,02 0,05 0,1 B : The difference of lip height B 0,005 0,02 0,1 0,05 0,02 0,1 Peripheral Run-outAccuracy Drill run-out when mounted onthe machine spindle must be Peripheralrun-out Hole expansion Horizontal cutting force when Tool Rotates within 0,03mm. If the run-out is (mm) 0 0,05 (mm) 0 10 (kg) large, the drilled hole will also be large causing an increase in the 0,005 horizontal cutting force, which may result in drill breakage if the 0,09 machine or work clamping is not rigid. Drill: MDS120MK Work material: C50 (230HB) Cutting data: vc=50 m/min, f=0,3 mm/rev, doc =38mm Run-out: within 0,03mm Water soluble Peripheral Run-outAccuracy When use on a lathe, run-out at point A must be within0,03mm, this value must be similar when taken atwhen Workpiece Rotatesposition B.ChuckRun-out: within 0,03mm Influence of WorkpieceSurface Workpiece with slanted or uneven surface (Entrance) (Exit) If the surface of the hole entrance or exit is slanted or uneven, decrease the feedrate to 0,1~0,15mm/rev at these points. How to Use Long Drill When using a long drill (e.g. XHGS type and Hole bend Problem XHT type), DAK type or SMDH-D type drills at high rotational speeds, the run-out of the drill tip may cause a position shift at the entry point making the drill hole bent and resulting in drill Position shift breakage. Remedies Method 1. No rotation Step Step Step 1 2 3 Pilot hole 2~3 mm (1D, Same dia.) Drilling at recommended Short drill condition Method 2. Low rotational speed minimizes centrifugal forces and prevents drill bending. Step 2~3 mm Step 1 2 Drilling at recommended (n = 100~300 rpm) (f =0,15~0,2 mm/rev) condition N15 Guidance Technical

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части