Общий каталог Sumitomo 2018 - 2019 - страница 493

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

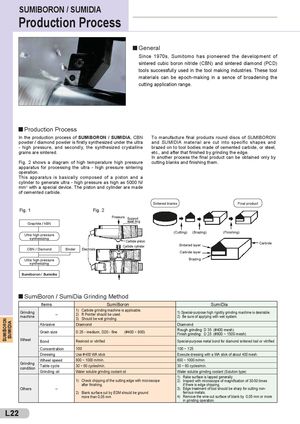

SUMIBORON / SUMIDIA Production Process - General Since 1970s, Sumitomo has pioneered the development of sintered cubic boron nitride (CBN) and sintered diamond (PCD) tools successfully used in the tool making industries. These tool materials can be epoch-making in a sence of broadening the cutting application range. - Production Process In the production process of SUMIBORON / SUMIDIA, CBN To manufacture final products round discs of SUMIBORON powder / diamond powder is firstly synthesized under the ultra and SUMIDIA material are cut into specific shapes and - high pressure, and secondly, the synthesized crystalline brazed on to tool bodies made of cemented carbide, or steel, grains are sintered. etc., and after that finished by grinding the edge. In another process the final product can be obtained only by Fig. 2 shows a diagram of high temperature high pressure cutting blanks and finishing them. apparatus for processing the ultra - high pressure sintering operation. This apparatus is basically composed of a piston and a cylinder to generate ultra - high pressure as high as 5000 N/ mm2 with a special device. The piston and cylinder are made of cemented carbide. Sintered blanks Final product Fig. 1 Fig. 2 Pressure Support Graphite / hBN steel ring (Cutting) (Brazing) (Finishing) Ultra high pressure synthesizing Carbide pistonCarbide cylinder Sintered layer Carbide CBN / Diamond Binder Electrode Carbide layer Ultra high pressure Brazing synthesizing Sumiboron / Sumidia - SumiBoron / SumiDia Grinding Method Items SumiBoron SumiDia Grindingmachine 1) Carbide grinding machine is applicable.–2)R Pointer should be used.3)Should be wet grinding.1) Special-purpose high rigidity grinding machine is desirable.2)Be sure of applying with wet system. Abrasive Diamond Diamond Grain size D 25 - medium, D20 - fine (#400 ~ 800) Rough grinding: D 35 (#400 mesh)Finish grinding:D 25(#800 ~ 1500 mesh) Wheel Bond Resinoid or vitrified Special-purpose metal bond for diamond sintered tool or vitrified Concentration 100 100 ~ 125 Dressing Use # 400 WA stick Execute dressing with a WA stick of about 400 mesh. Wheel speed 800 ~ 1000 m/min. 800 ~ 1000 m/min. GrindingconditionTable cycle 30 ~ 60 cycles/min. 30 ~ 60 cycles/min. Grinding oil Water soluble grinding coolant oil Water soluble grinding coolant (Solution type) 1) Rake surface is lapped generally 1) Check chipping of the cutting edge with microscope 2) Inspect with microscope of magnification of 30-50 times after finishing. if there is edge chipping. Others – 3) Edge treatment of tool should be sharp for cutting non- 2) Blank surface cut by EDM should be ground ferrous metals. more than 0,05 mm 4) Remove the wire-cut surface of blank by 0,05 mm or more in grinding operation. L22 SUMIBORON SUMIDIA

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части